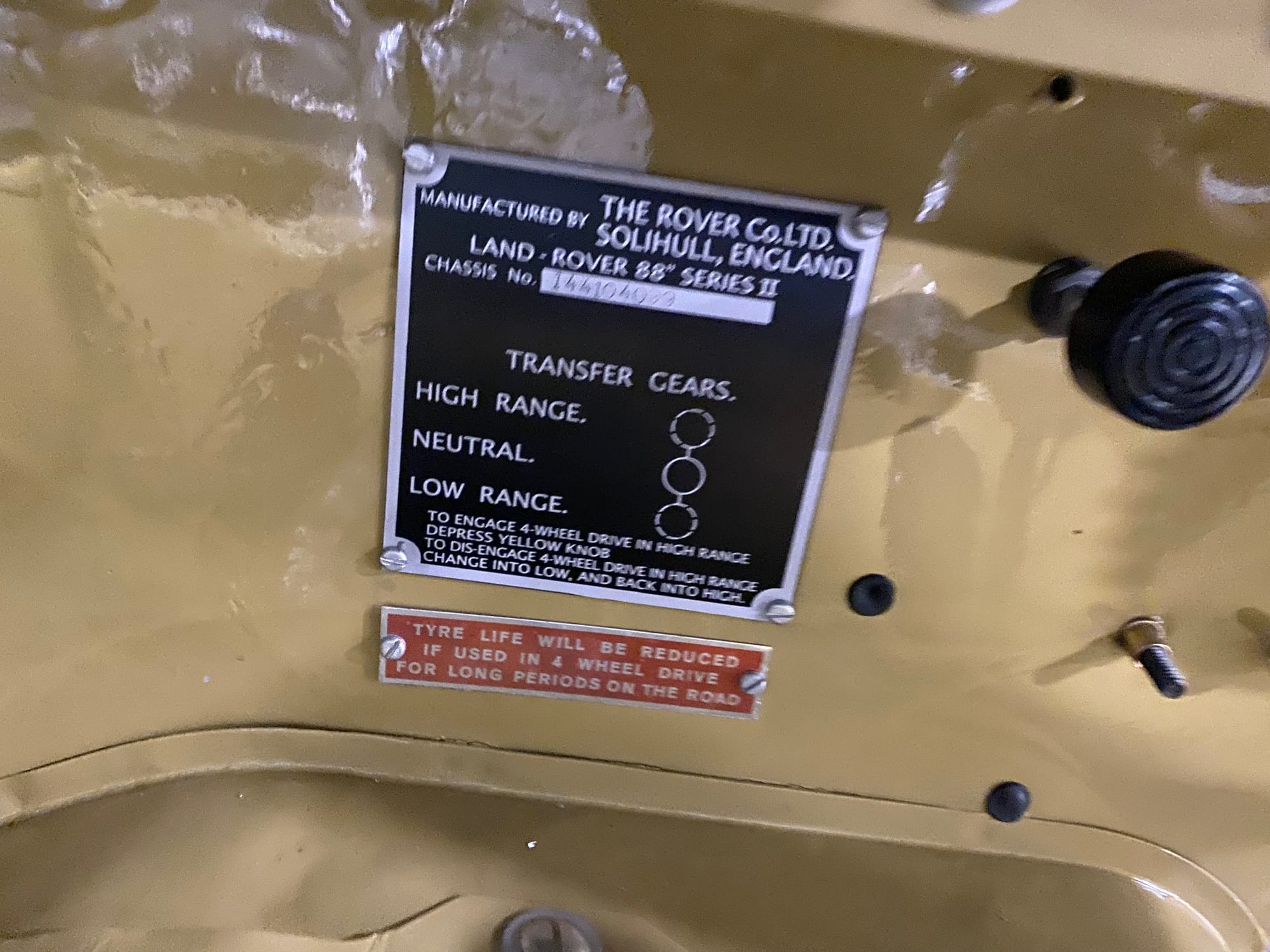

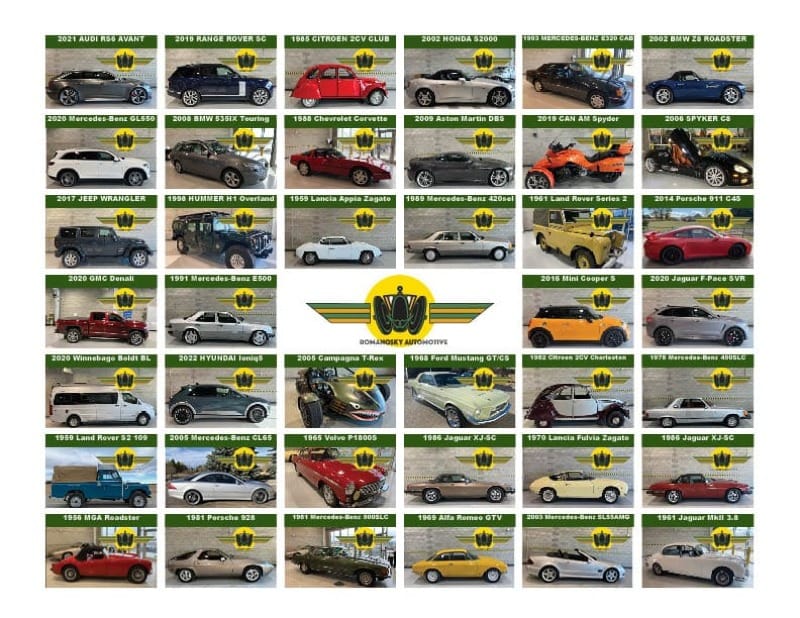

1961 Land Rover Series 2 88"

VIN #1441-04099

88" Short Wheel Base LHD 'Utility' with Canvas Tilt

Greensand (Jaguar E Type Colour) with Olive Canvas

Ground Up Restoration from 2018-2023

Sympathetically updated with 8:1 compression 2.25L Series 2a Engine, Weber Carb

Large collection of NOS parts used

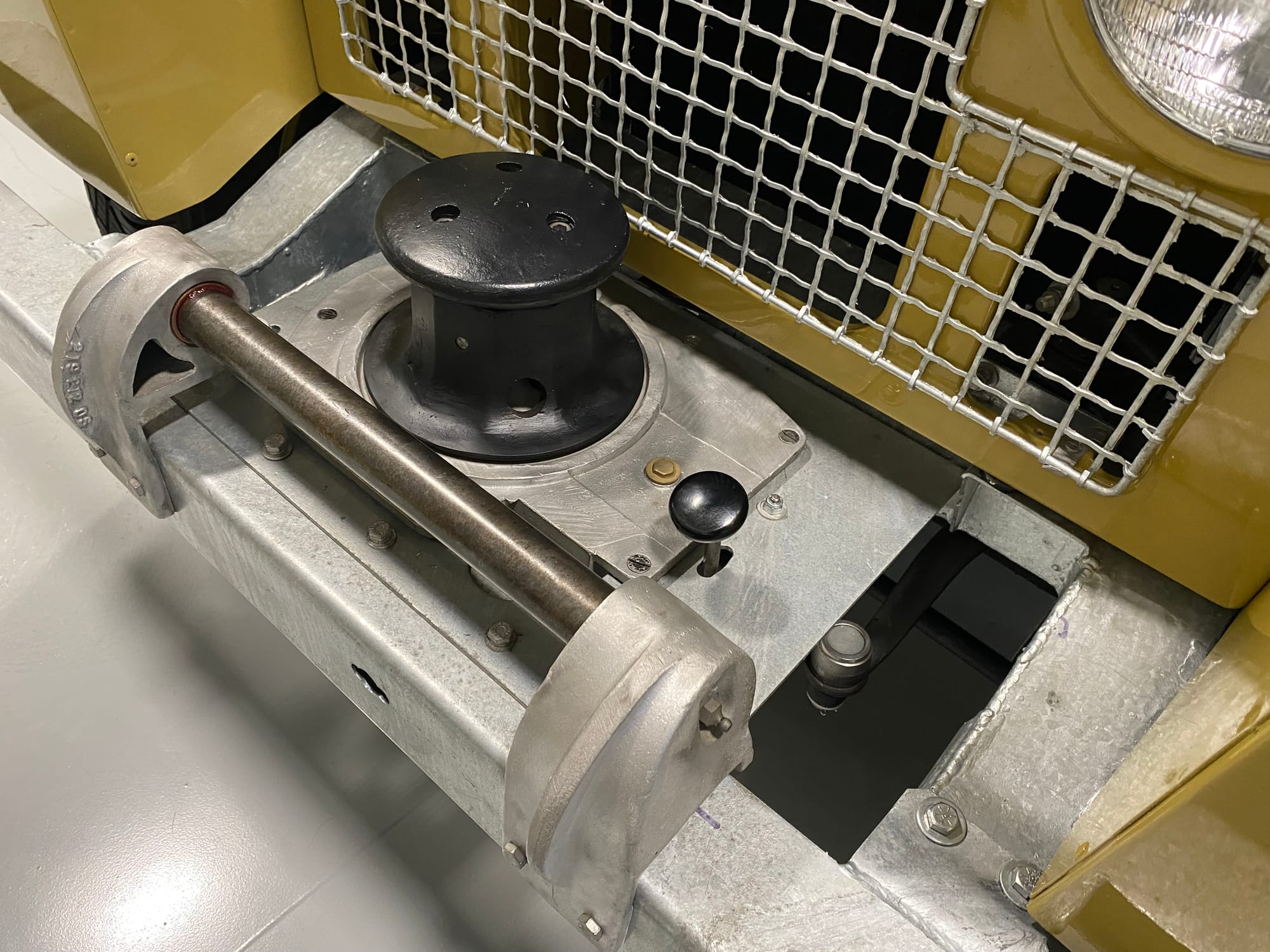

Rare Capstan Winch, restored and operational

Montana Title, located near Sweetgrass, MT

Offered on Hemmings On-Line for $USD100,000

https://www.hemmings.com/listing/1961-land-rover-88-297455

ABOUT THE SERIES LAND ROVER

Before Defender, Discovery and Range Rover there were Rover cars and Land Rover off-road vehicles.

The Rover car company, looking to start up automobile production after World War II, landed on the idea of an all purpose, off-road utility vehicle loosely based on the American Jeep. The first Land Rovers had the same 80” wheelbase as a Jeep, and were similar in appearance, but the Rover used a much more robust boxed steel chassis and featured aluminum body panels.

These ‘British Jeeps’ were popular in the Commonwealth countries such as Australia and Canada and were used extensively for light commercial work in mines, forestry and utilities. They were also the choice for explorers and adventurers, and it didn’t take very long after the 1948 introduction for Land Rovers to be spread throughout the world - and often in the most remote places.

The original Land Rover with an 80 inch wheelbase gave way to the 86” and 88” versions and the addition of a 107” station wagon and pick up. The Rover i.o.e. 1.6 Litre engine was enlarged to 2.0 Litres. In the late 1940’s and early 1950’s Rovers were marketed to industry and government as utility vehicles.

In April 1958, the ‘new’ Land Rover was introduced, now called the Series 2. Retroactively, earlier Land Rovers were now referred to as Series 1.

The Series 2 Land Rover was styled with the aim of appealing to a new consumer market, and featured a slightly more comfortable cabin and some concessions to convenience where the Series 1 had none. The gas cap was mounted on the outside of the vehicle, instead of beneath the passenger seat for instance!

A new 2.25L OHV engine was designed - it’s 77hp offering 50% more power than the old 2.0L i.o.e. unit. Outfitted with the new engine, the Land Rover could maintain highway speeds, where the Series 1 was limited to about 55mph flat out.

There were not enough of the new 2.25L 4 cylinder engines to go around, so Rover installed the new engine in the heavier, long wheel base pick ups and station wagons first, while the short wheel base 88” Land Rovers were shipped with the 2.0L i.o.e unit for the first couple of years.

In late 1961 a host of changes were made to the Series 2 to make it a Series 2a. These mostly involved the engine, as it was redesigned to share parts with a new diesel engine of the same displacement. The Series 2a name was then used up until 1971 when the Series 3 was introduced. A Series 2 and a 2a Land Rover are mostly indistinguishable externally, apart from some small details.

Because the original 2.25 Litre gas engine was revised relatively early on in its life, Rover stopped suppling parts for it, and supplied updated ‘2a’ service items instead.

There were about 110,000 Series 2 Land Rover produced in all variations, with about 60,000 of those being the 88” versions. There were 430,000 Series 2a Land Rovers produced from 1961-1971.

The Series 2a became the Series 3 in 1971 with some exterior changes including a grill made from plastic, further interior refinements and a fully synchronized-4 speed gearbox.

The Series 3 was replaced by the ‘Ninety’ and ‘One Ten’ in 1985. These vehicles featured a revised coil sprung suspension and could now be had with V8 power.

In 1990 the Defender name was added to differentiate it from the new Discovery model. Today, ‘Series Land Rovers’ denote the original body style from 1948-1985, and ‘Defender’ denotes the coil sprung versions built from 1984-2016.

This Land Rover’s VIN, #1441-04099, denotes it as a LHD 88” Utility Petrol Export model made in mid 1961, shortly before the model was changed to the ‘2a’. The last recorded VIN of a Series 2 LHD Petrol is 1441-05602, meaning this vehicle was one of the last 1,500 produced. Apart from the engine, there is very little to distinguish this last Series 2 from the first 2a made in the same calendar year.

As these early Land Rovers were ‘working vehicles’, very few survive in their original condition. Most were modified to continue to be useful and at the end of their life they were scrapped or abandoned.

Thanks to its iconic status, and companies like Dunsfold Land Rover and Rovers North, enthusiasts were able to rescue these vehicles and put them back into service. This book tells of one such rescue were ‘04099’ had been partially disassembled and was in a pretty awful state.

LAND ROVERS IN CANADA

THE RESTORATION (2018-2023)

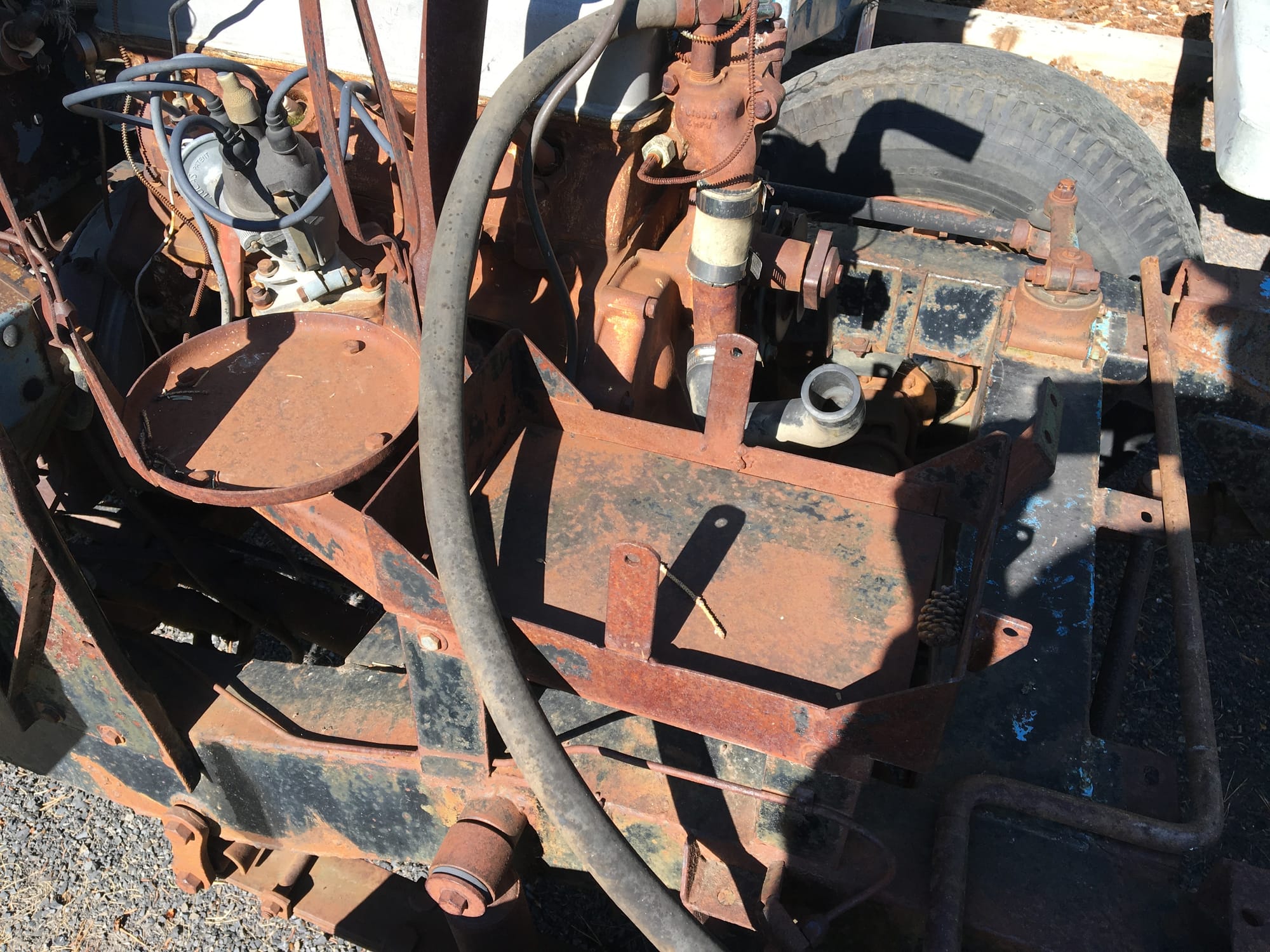

AS FOUND

The chassis of ‘04099’ was in remarkably good condition. It had brackets welded to the front horns for a snow plow. It had much of the original black paint still left on it, and only light corrosion. Repair was needed to straighten the passenger side rear cross member which had been bent.

The steel bulkhead was in remarkably good condition with just the floors that needed replacing.

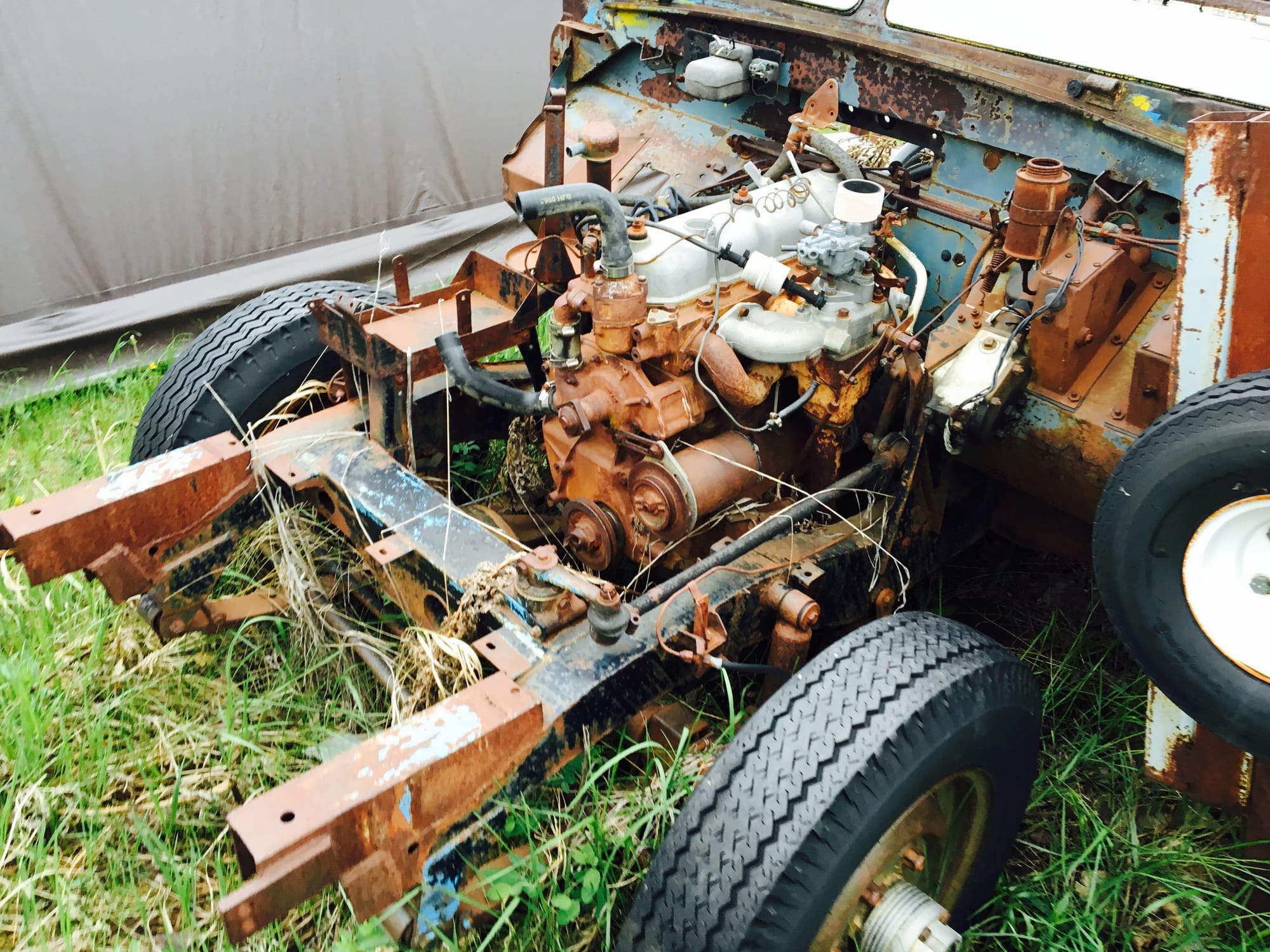

DONOR VEHICLES

Dead Land Rovers are relatively cheap to buy, and reasonably plentiful in Alberta and British Columbia where most of them lived. They are almost all modified to some degree and the aluminum panels are usually completely beat up. Unlike steel, aluminum panels are very difficult to repair as they don’t have a ‘memory’ like steel.

The steel frames were very susceptible to corrosion and most have had significant chassis repairs at some point in their lives. Very few restored vintage Land Rovers have their original frames.

To restore a Series Land Rover, it is advantageous to start with several vehicles and mix and match the best parts. Their ‘Meccano’ nature make this a practical proposition. You can’t do the same thing with most other collectibles as even the basket cases are expensive and they are welded, not bolted together like a Land Rover.

These photos show a 1967 Series 2a which donated its rear box and bonnet, and a 1964 2a which donated its doors and seat box, among many other smaller parts.

CHASSIS

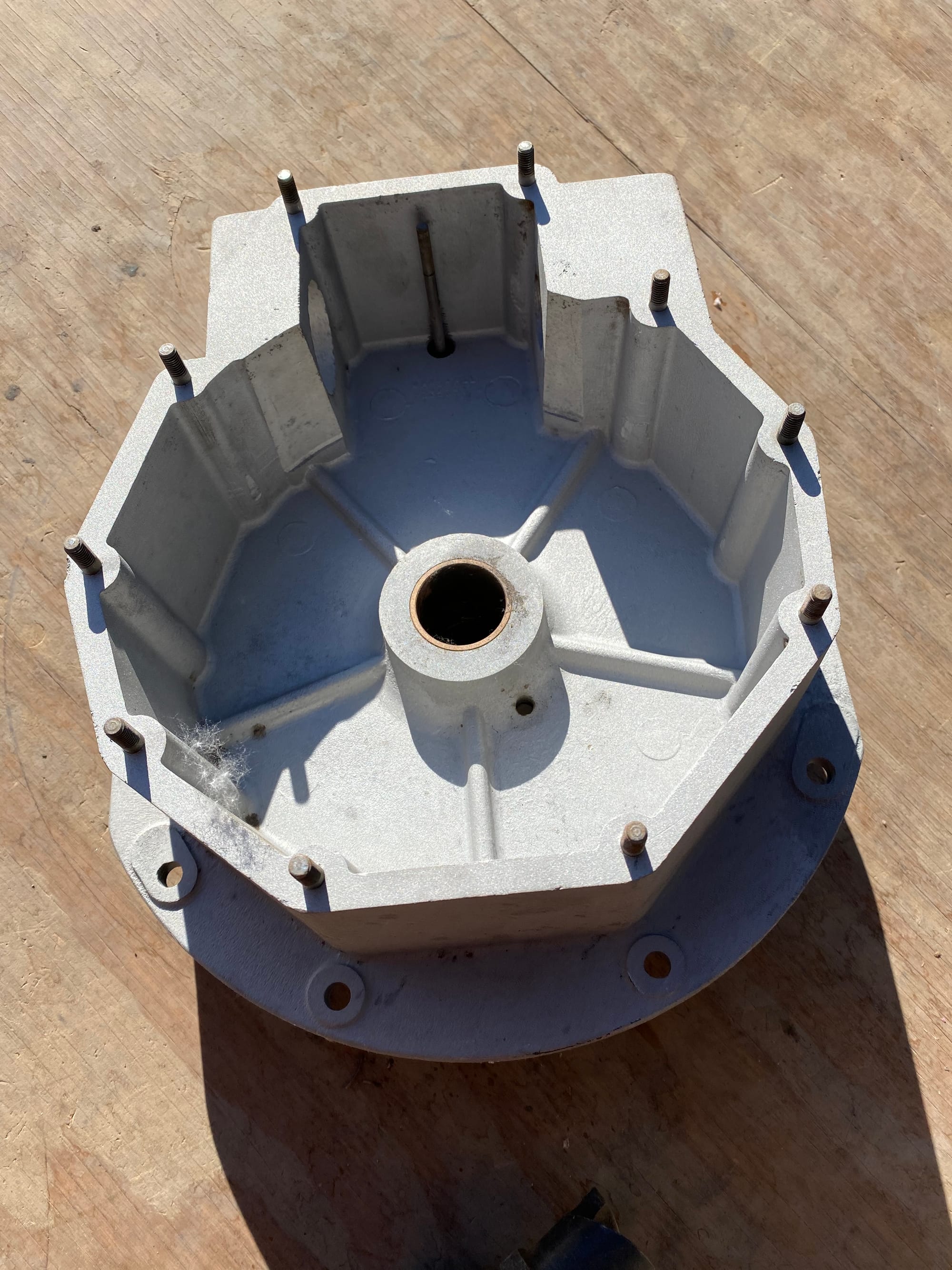

The chassis from ‘04099’ was completely stripped and sand blasted. The front snowplow brackets were cut off and the front ‘horns’ cleaned up. A new rear cross member was fabricated and replaced the original that was compromised.

After the chassis was dimensionally checked it was sent for hot-dip galvanizing along with the bulkhead and much of the exterior trim and fittings. This is the same process as used in chain link fences and other industrial applications where steel is submerged in a pool of molten zinc.

BULKHEAD

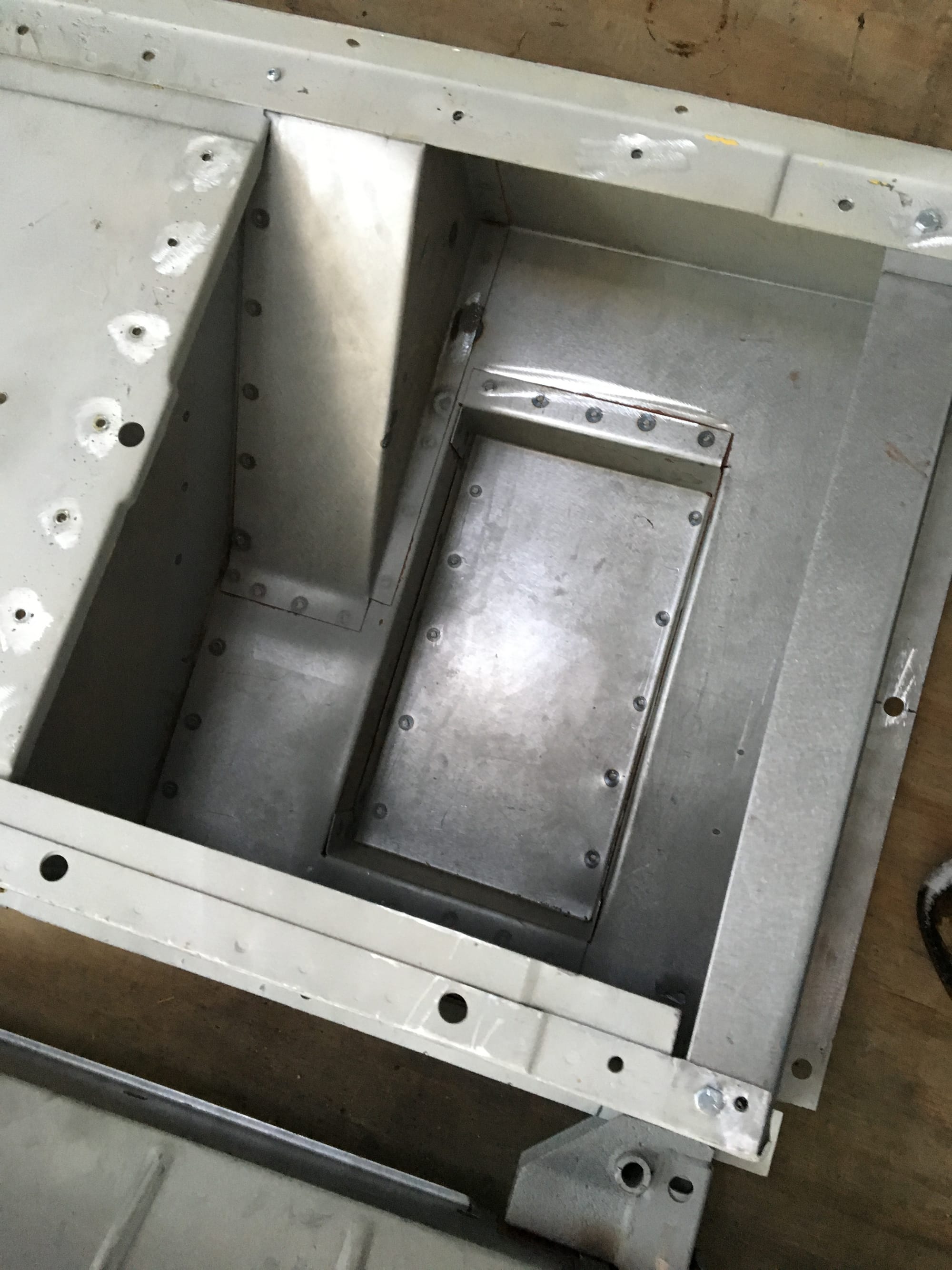

The bulkhead on Series Rovers is susceptible to rust in the floors and lower portions. This example survived well, but it was still deemed desirable to replace the floors as the metal was thin after sandblasting.

While the chassis was painted black from the factory, the bulkhead was painted body colour. For this restoration both items were galvanized, but the bulkhead was then painted. The bulkhead on most Series Land Rovers is normally not galvanized as the hot-dipping creates problems with captive nuts that hold the fenders on. In this instance the extra process was undertaken for the ultimate in rust protection. This added a considerable amount of work to chase the threads in all the captive nuts, and extra prep work on the galvanized finish before paint.

The front radiator support was NOS and it, along with the front bumper, were also galvanized. This Rover will not rust!

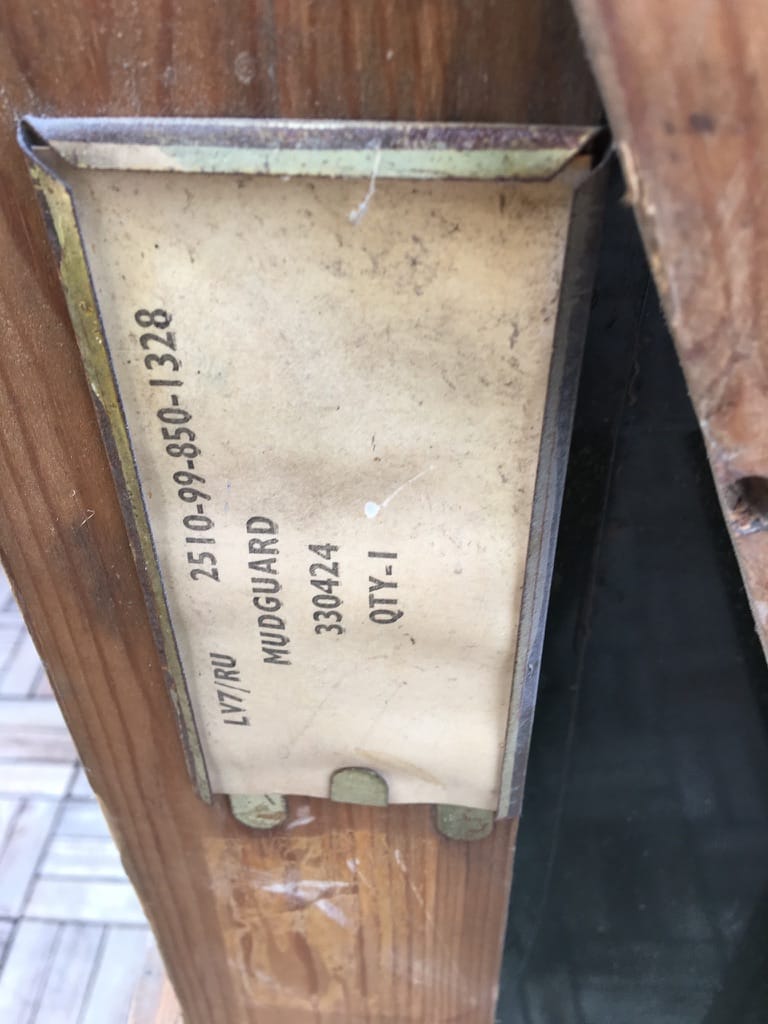

FRONT FENDERS

The front fenders, aluminium as is the rest of body on a Series Land Rover, are rarely found in good condition. We were fortunate that Rovers North had one set of NOS fenders in stock, and while they were expensive, I had to have them for this restoration. They came in their original crates, with the tags date stamped for the year 1972. Pangolin 4x4 also supplied a NOS front grill panel and other NOS parts. The fenders were painted inside and out, even though they would have been bare aluminum from the factory.

SEAT BOX, DOORS AND FLOOR PANELS

The seat box, doors and floor panels - you guessed it - are also hard to come by in good condition. The doors in particular as they have a steel frame with an aluminium skin. The two different kinds of metal react and form electrolytic corrosion which turns the aluminum into a white powder. For this Rover we had to re-make the metal frames and make a new door skin - not an easy job.

There were probably 40 hours put into just the two doors alone. For the floors and seat panels it was a matter of taking the best pieces from the three Land Rover donors and cleaning the metal up before paint.

Much of the seat box had to be fabricated with care taken to use the same-type solid rivets as factory.

REAR BOX

The rear box is probably the most difficult part of the Land Rover to restore. There is no supplier of new rear boxes, and aluminum doesn’t survive very well when used in a utility vehicle. Most are full of patches and body filler.

The rear box on a Series Land Rover is constructed with riveted aluminum panels, aluminum longitudinal strengthening strips and steel cross members. Of course the steel and the aluminum react and eat through the bed floor.

We removed the floor and all the ribs, sandblasted and galvanized the steel bits, and let in a new floor from sheet aluminum.

The rear panels on the box were too far gone to salvage so new NOS panels were found and let in after drilling out the rivets of the damaged ones.

New aluminum strengthening ribs were fabricated and riveted to the floor.

GALVANIZED CAPPINGS

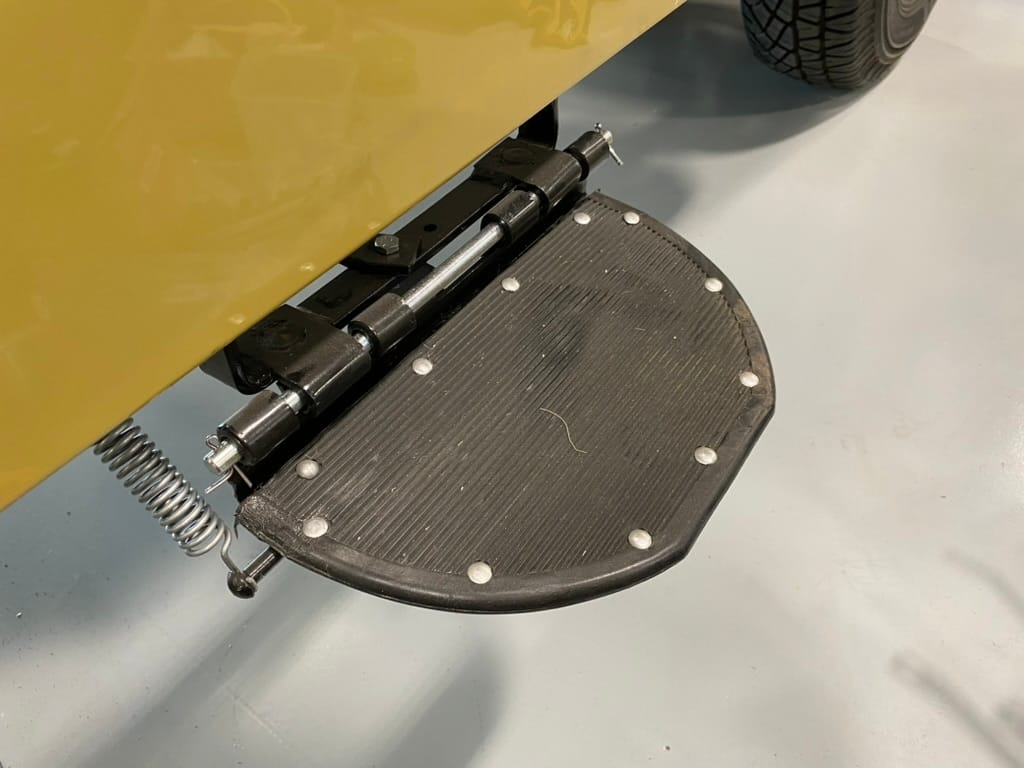

FOOT AND HAND BRAKE

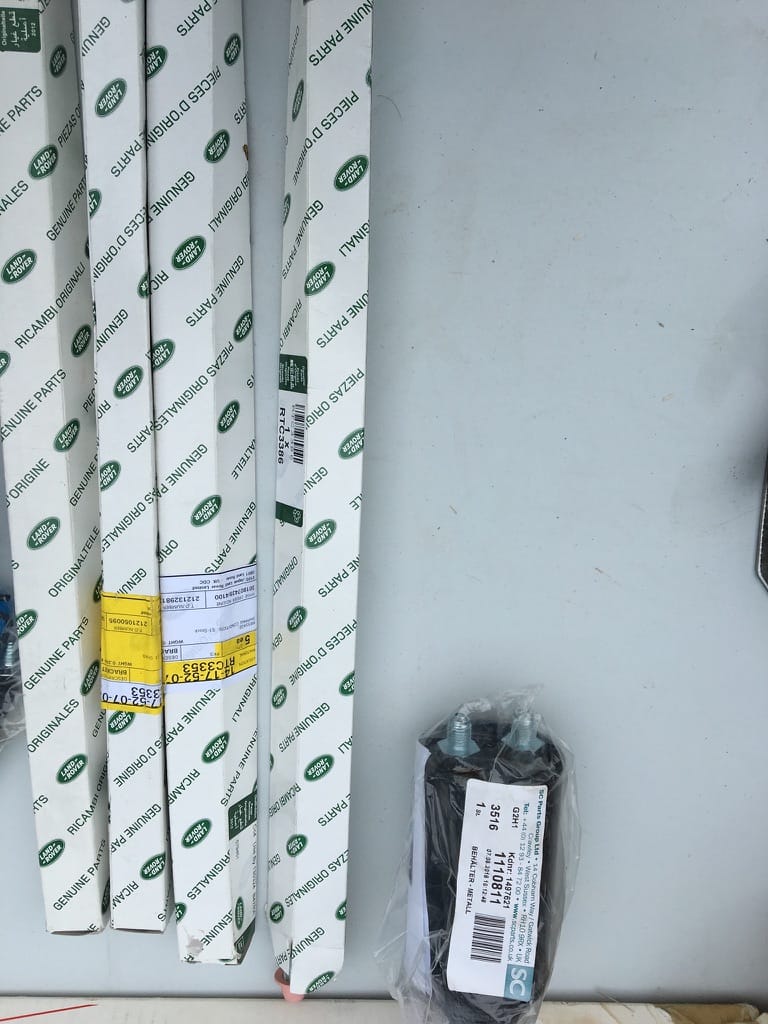

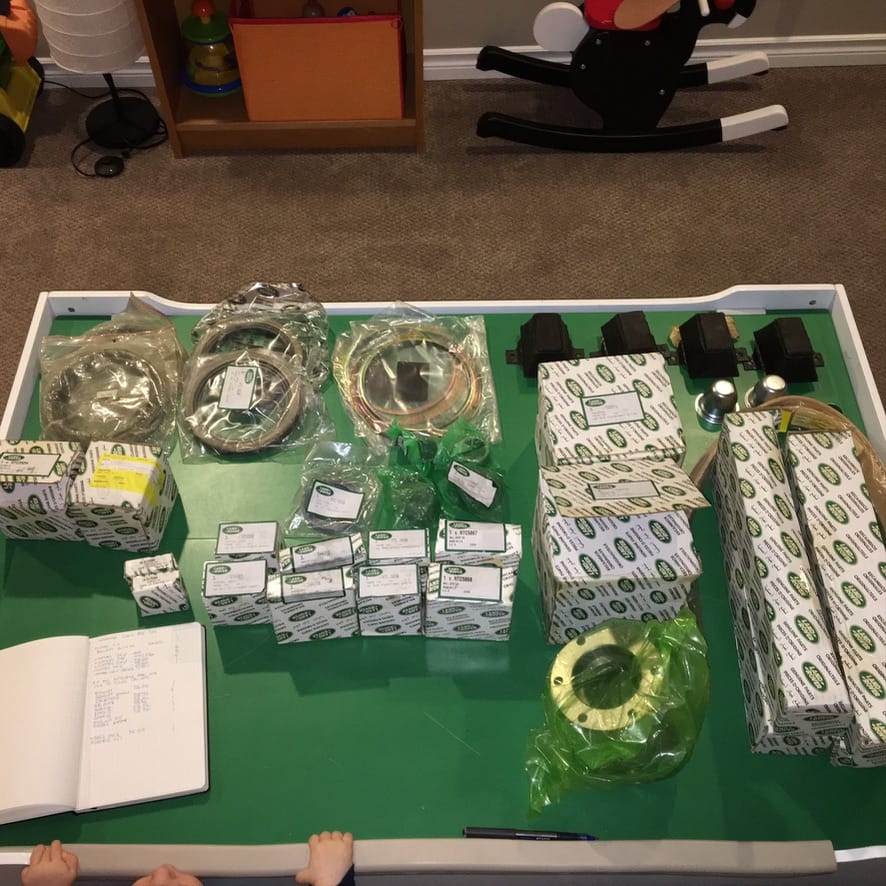

NOS PARTS

What makes this Land Rover restoration unique is the quantity of NOS parts used. There is very little of ‘04099’ that is new manufacture. This is a major difference from most restored Land Rovers that rely on aftermarket parts of indifferent quality.

The supply of just about all Series NOS parts has long been exhausted, but this collection of parts was accumulated over 30 years of buying from Rovers North from a Calgary collector. This was the same individual the chassis and one of the donor vehicles came from. He placed monthly orders in response to the catalogues Rovers North sent out.

The NOS parts on the Rover include, but are not limited to:

Lights, brake components, engine pistons, bearings, timing chain and seals, axle and hub components, interior gauges and switches, electrical cables, all rubber weather seals, front fenders and grill panel, throttle pedal and linkage, vent screens, fuel system parts, complete exhaust, 16 inch wheels, rear and side steps, mud flaps, manufacturer’s plates, shovel and mounting kit, Smiths safety gauge, warning lights and hundreds of smaller parts.

This Rover is a one-of-a-kind; it could not be made again as most of the NOS parts are no longer available.

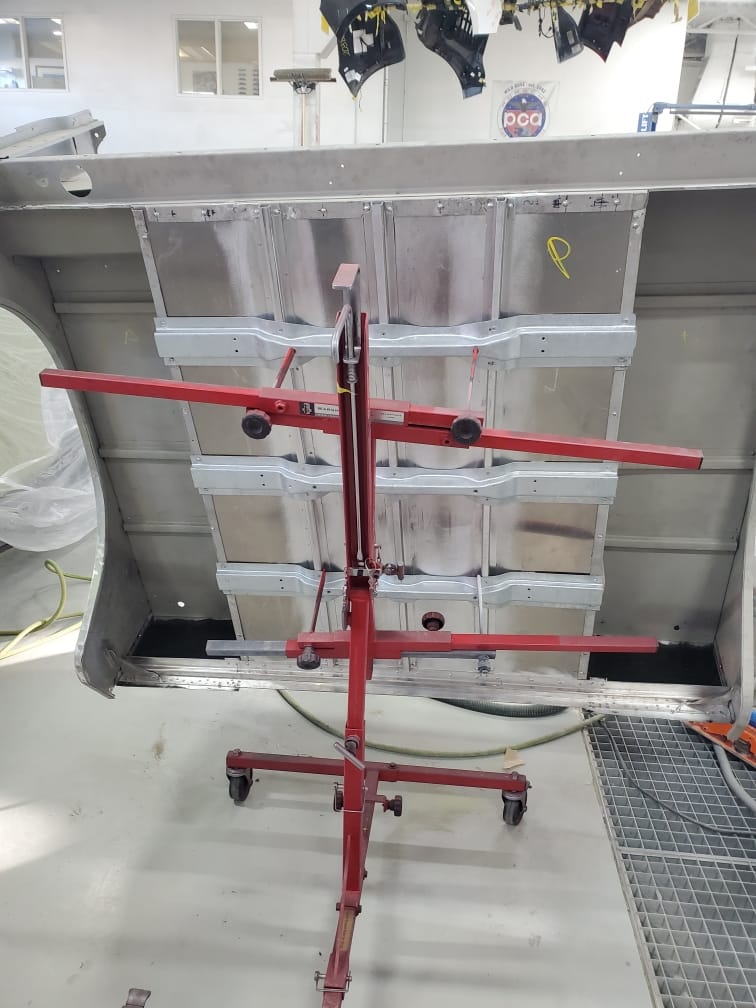

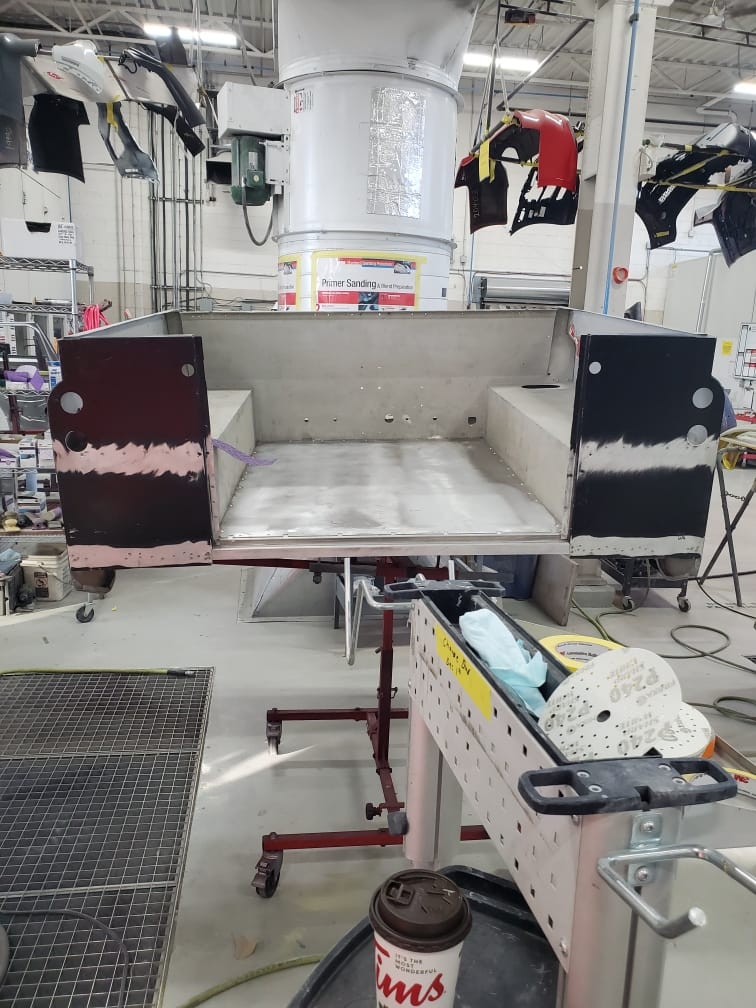

PAINTING

Painting was entrusted to Loc Ngo of Cosmos Collision in Calgary. Cosmos is the authorized Land Rover body repair facility, as well as for Jaguar, Porsche, Bentley and Tesla.

Cosmos does all of our paintwork, and had recently painted a 1973 Jaguar E Type V12 that we were also restoring concurrently with the Land Rover. The Jaguar was getting a colour change back to its original shade of Greensand. This particular car was also the first Series 3 E Type to have been built with the rare, Olive interior colour.

We decided to paint the Land Rover in the same colour as the Jaguar, as the colour seemed so ‘right’ for the Land Rover. On the E-Type it was quite controversial, but that is another story (book)! We also chose a dark olive for the canvas ‘tilt’ and matching door pockets.

We had a pair of British icons in the shop in matching colours!

ENGINE

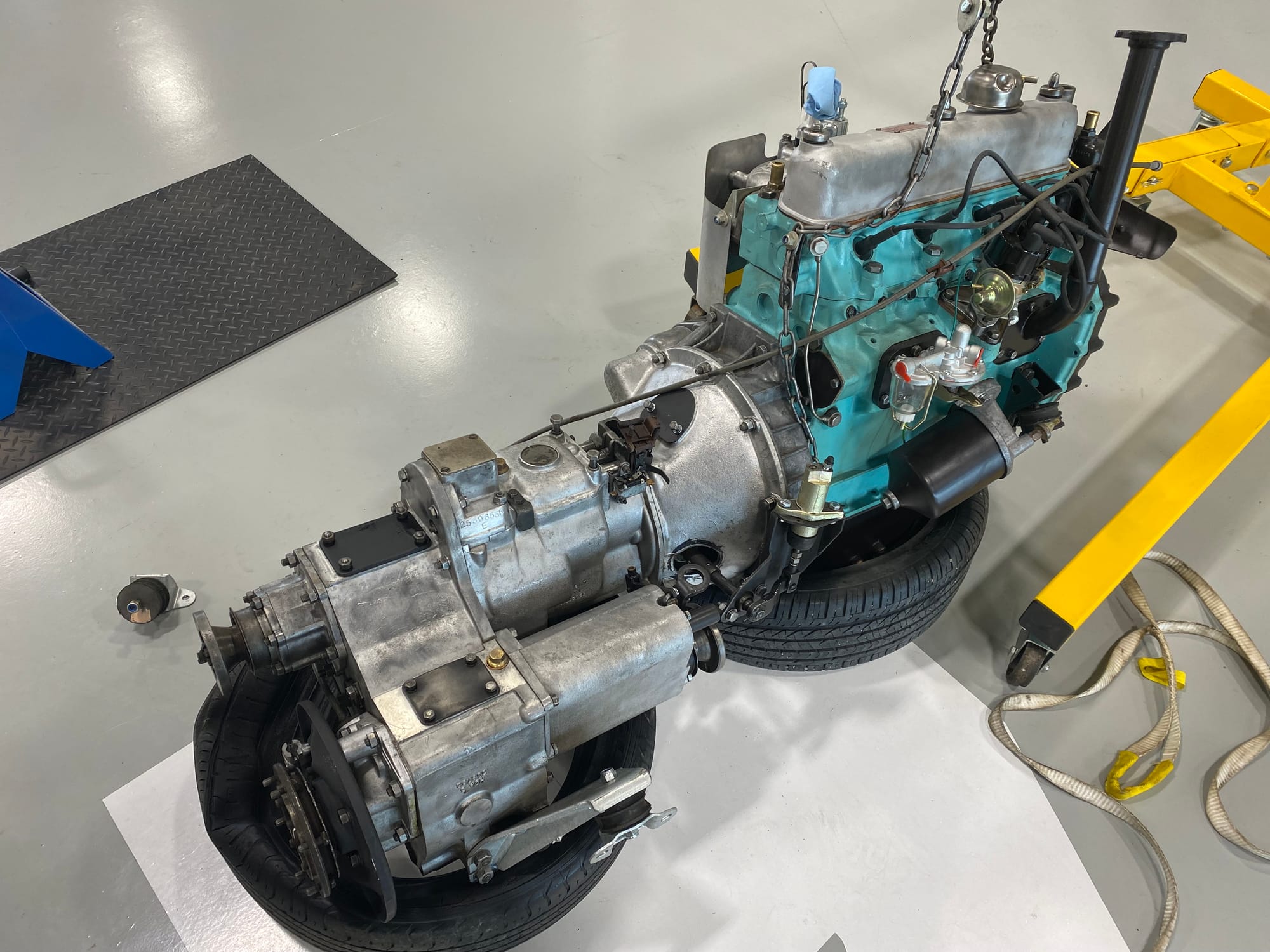

The original engine and gearbox on ‘04099’ were seized, and though the original components were cleaned up and kept with the vehicle, it made sense to put a Series 2a engine in the Land Rover as there are no parts available to fully rebuild a Series 2. Suppliers of remanufactured engines, like Turner in the UK, wouldn’t even take it as a core.

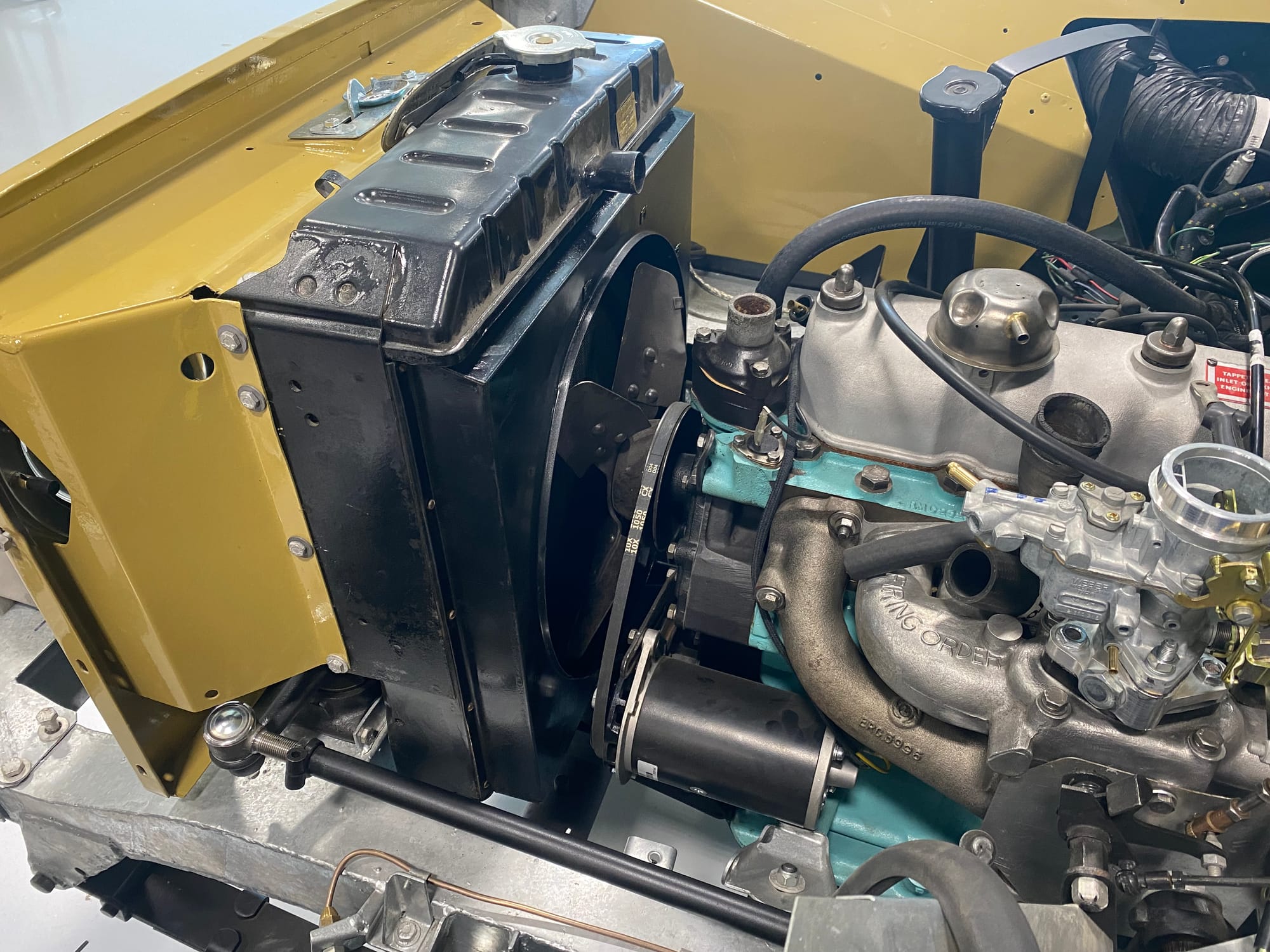

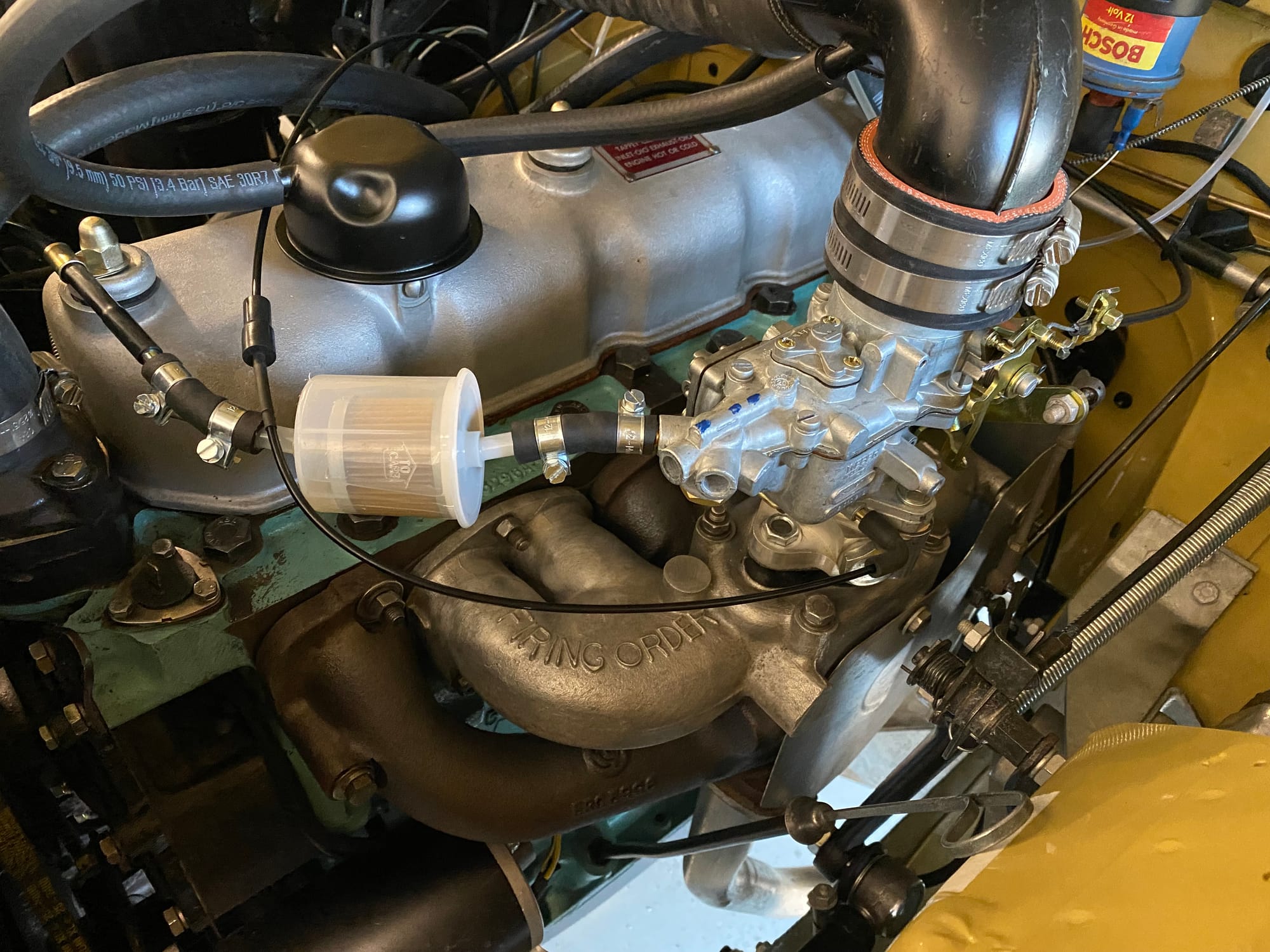

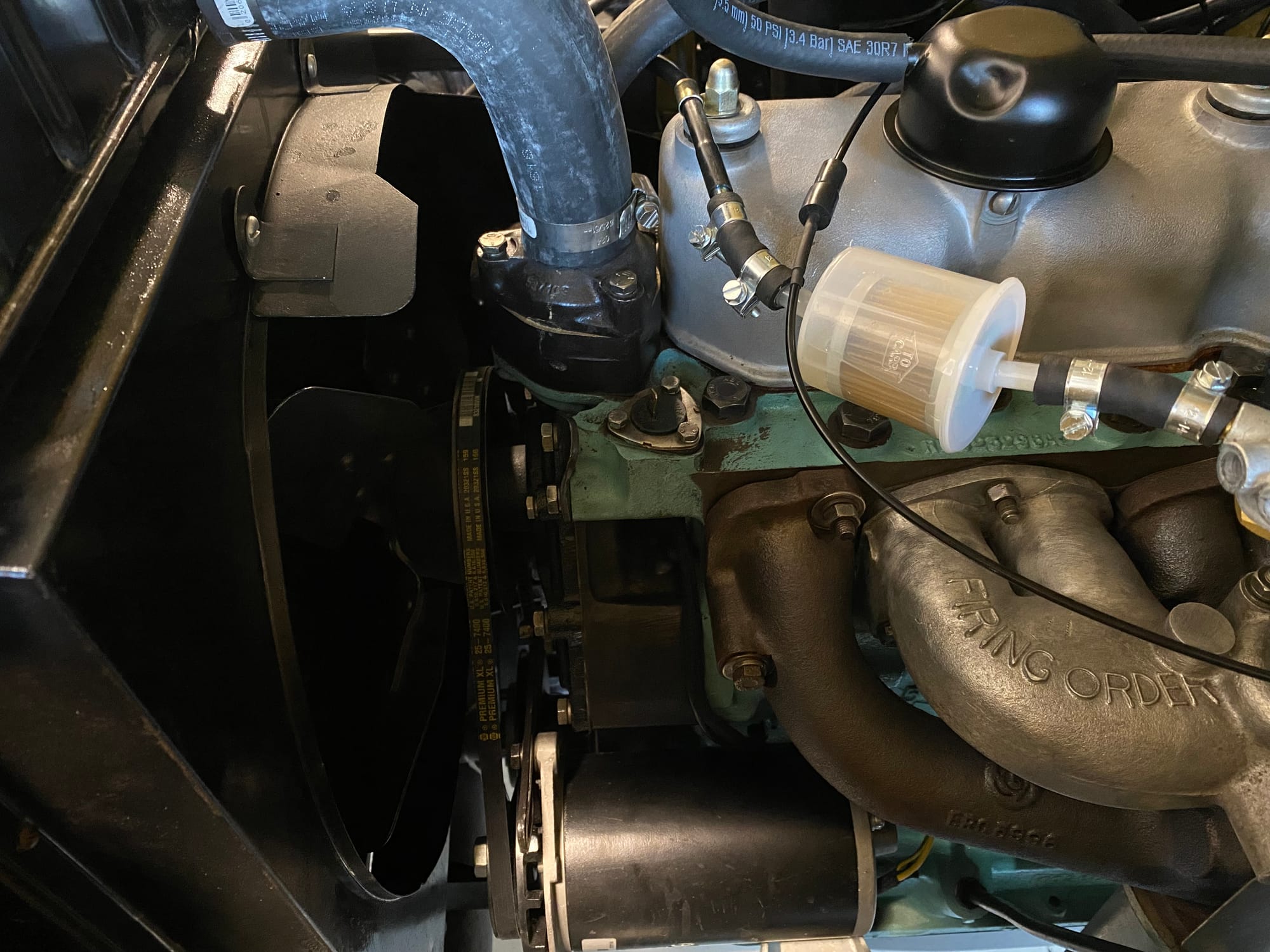

An 8:1 compression ratio (vs. 7:1 for the original) engine out of a 1970 Series 2a was sourced and completely rebuilt using NOS parts. The Weber carburetor and new distributor, water pump, fuel pump and coil were sourced from Rovers North and suppliers in the UK.

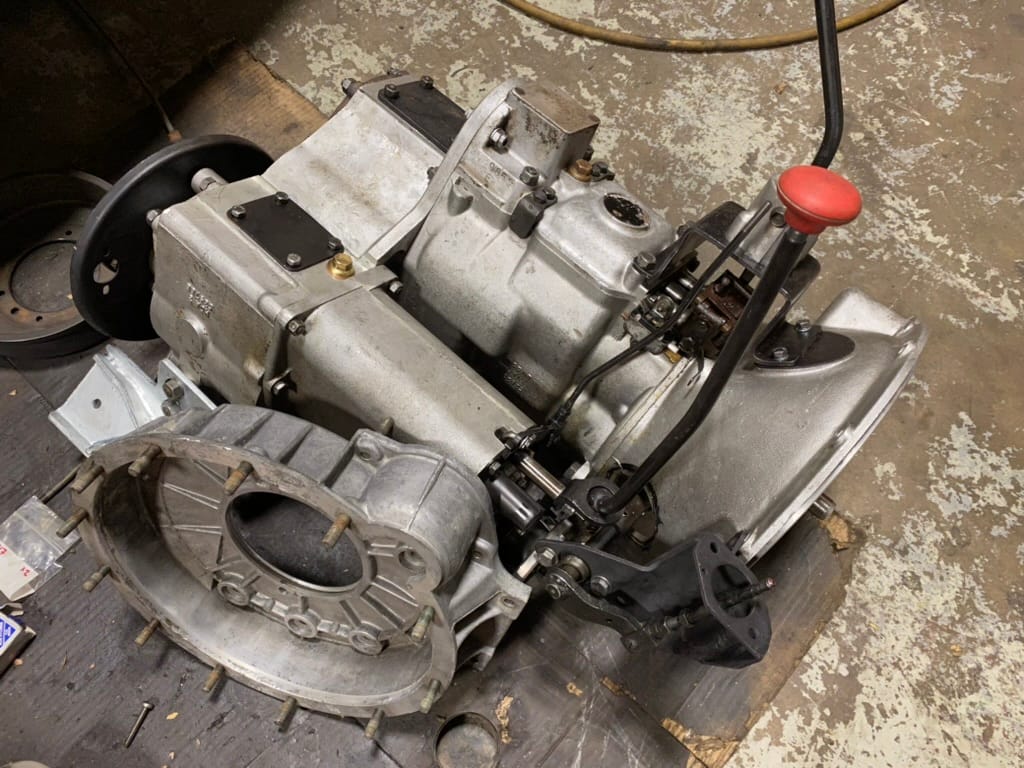

GEARBOX

The original 4 speed gearbox with synchromesh on the upper two gears was too far gone to practically rebuild, so only the casing was kept to be sold with the vehicle.

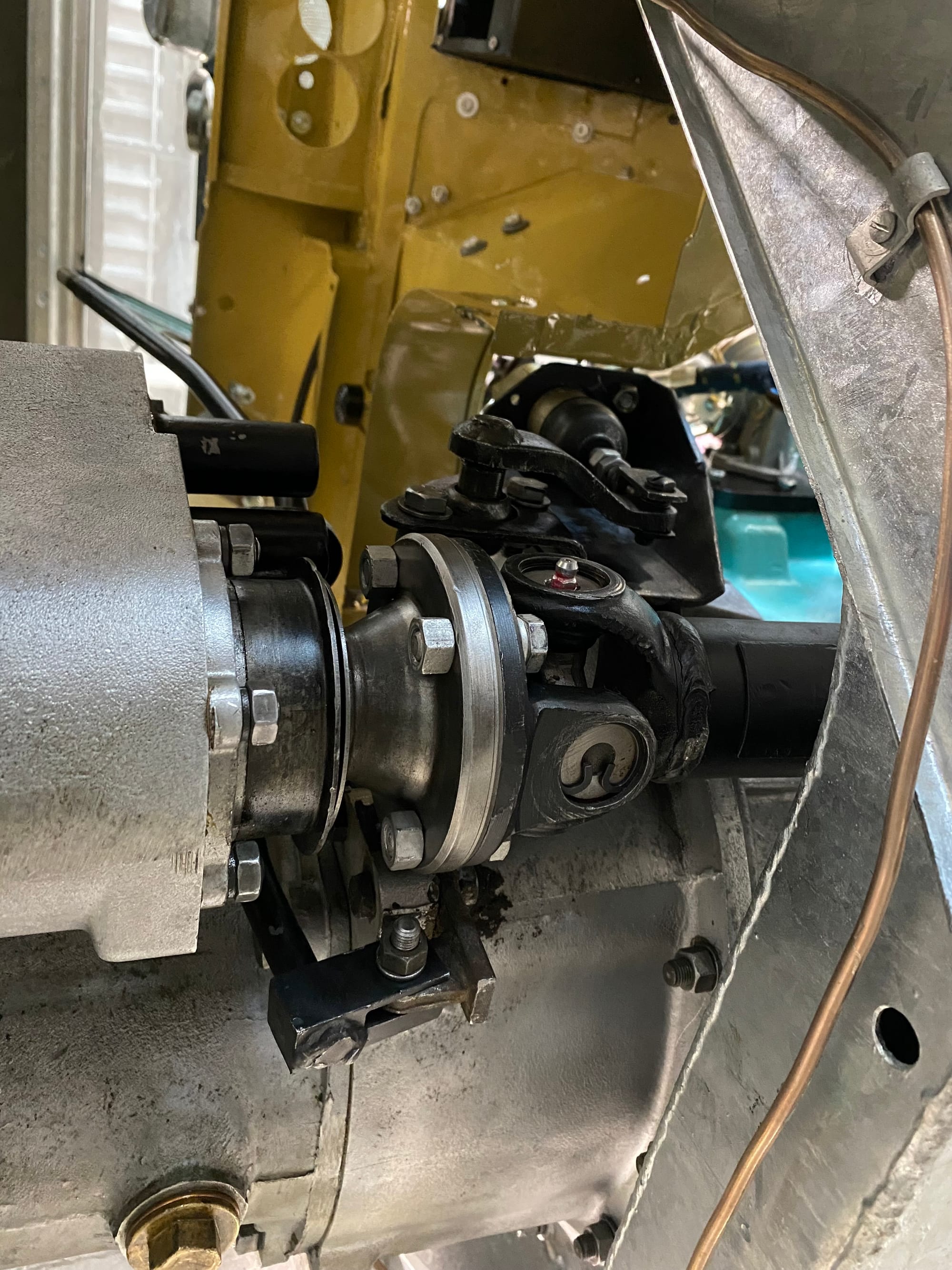

An ‘E’ Suffix gearbox, dating from 1967, was rebuilt with new bearings, seals and gears and is mated to the 2.25L 2a engine.

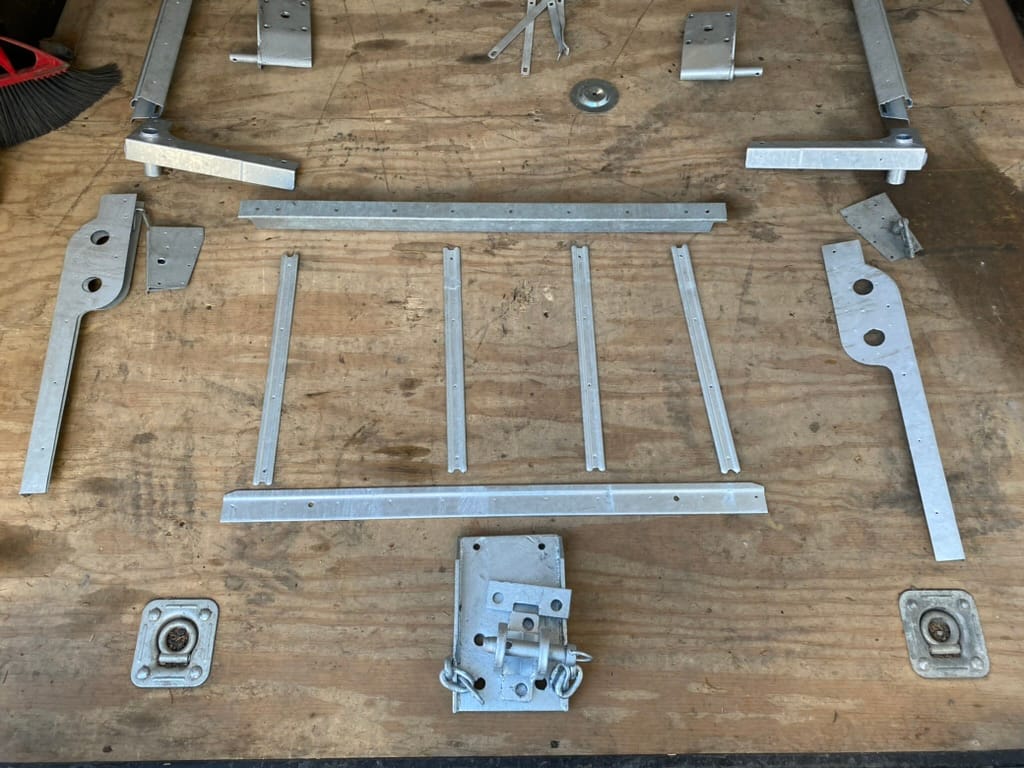

PARTS, PARTS, PARTS

Next, each part - either new, NOS or refurbished was laid out and inspected. The freshly Zinc re-plated zinc fasteners were sorted.

Most of the hard work was done, and satisfying work of bolting it all together was about to commence…

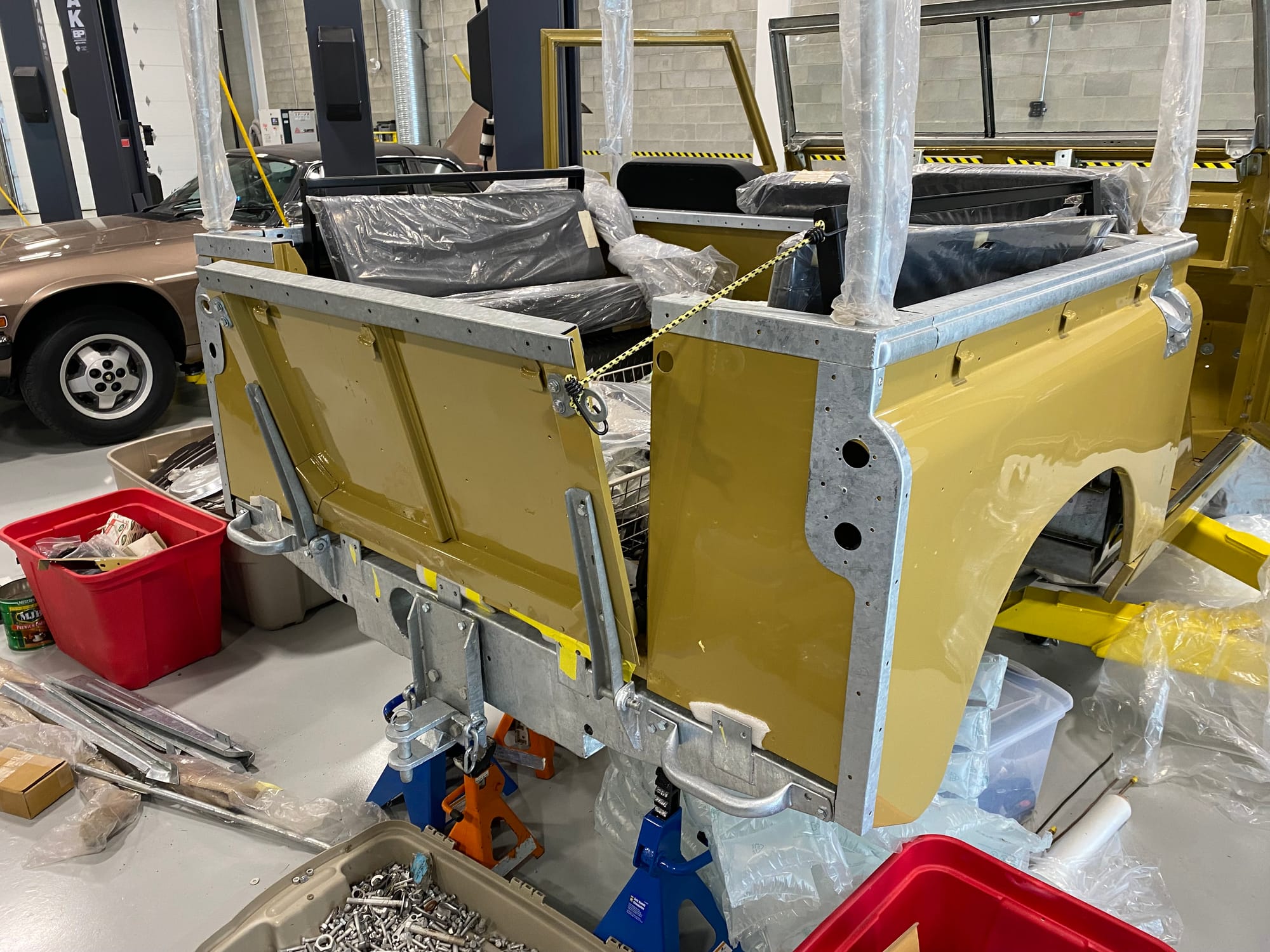

FINAL ASSEMBLY

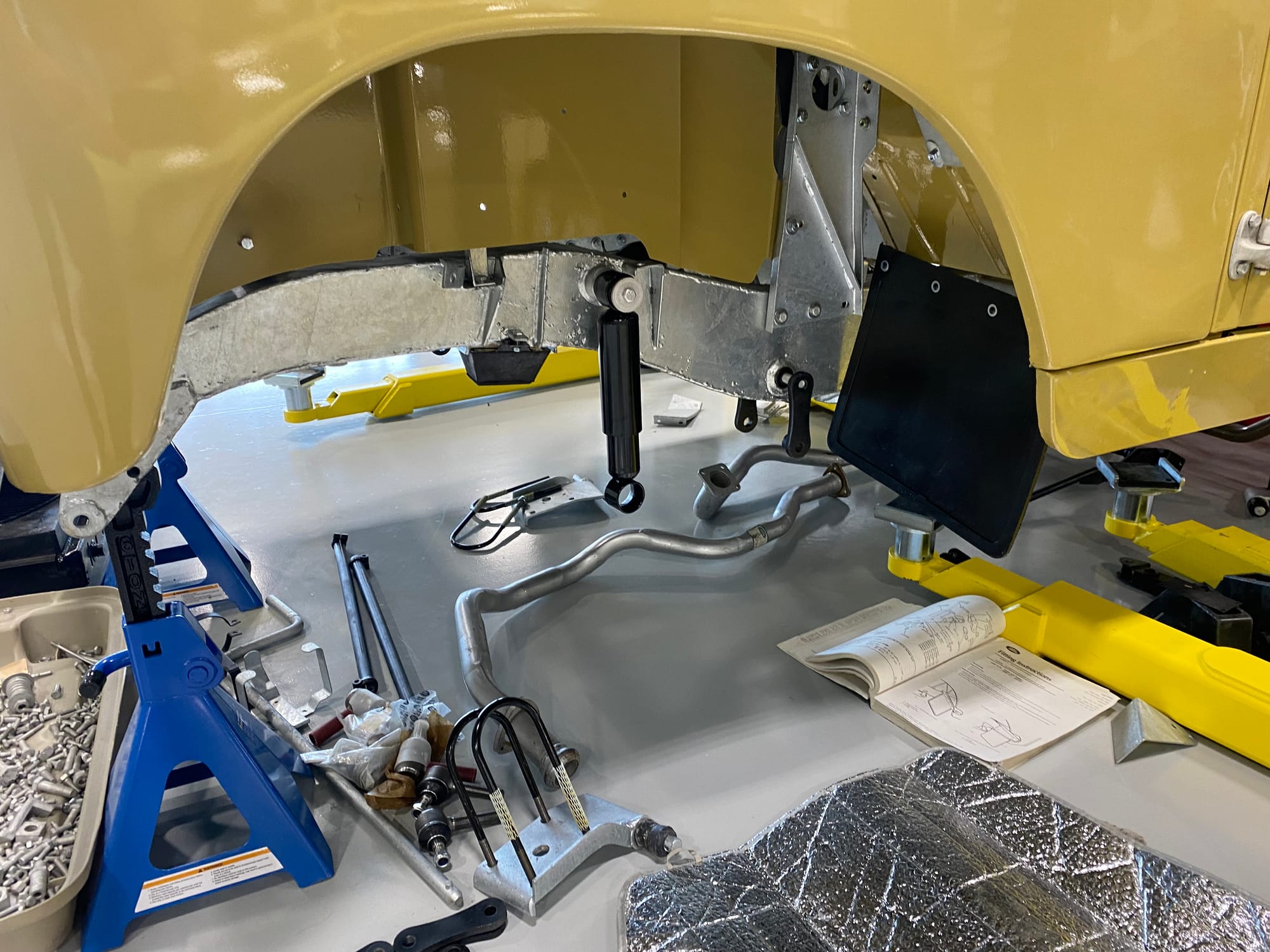

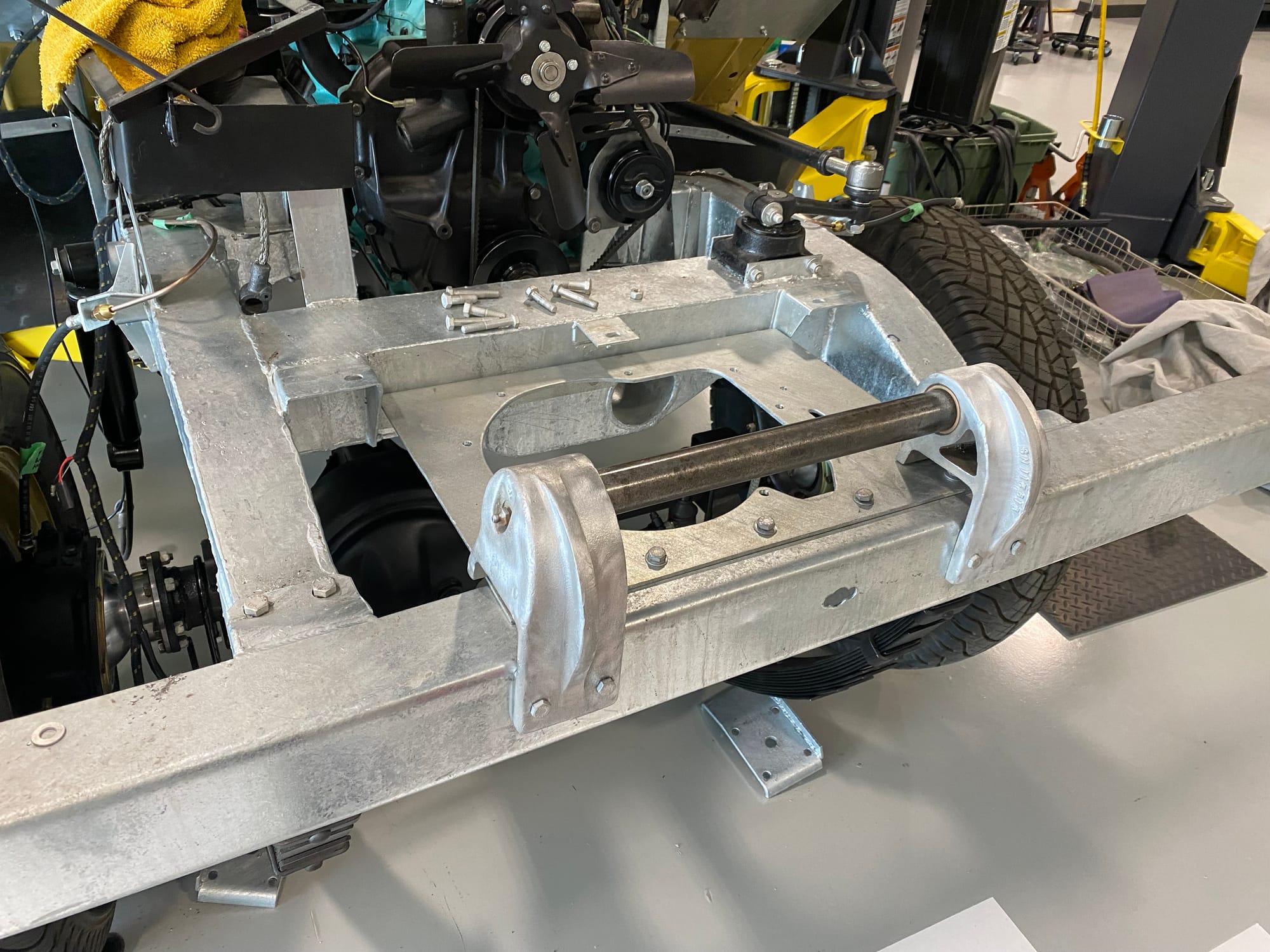

The fun begins! The Land Rover chassis is placed on a lift and all parts are bought together for final assembly.

Work started test fitting the bonnet, grill panel, rear box, seat box, bulkhead and windscreen.

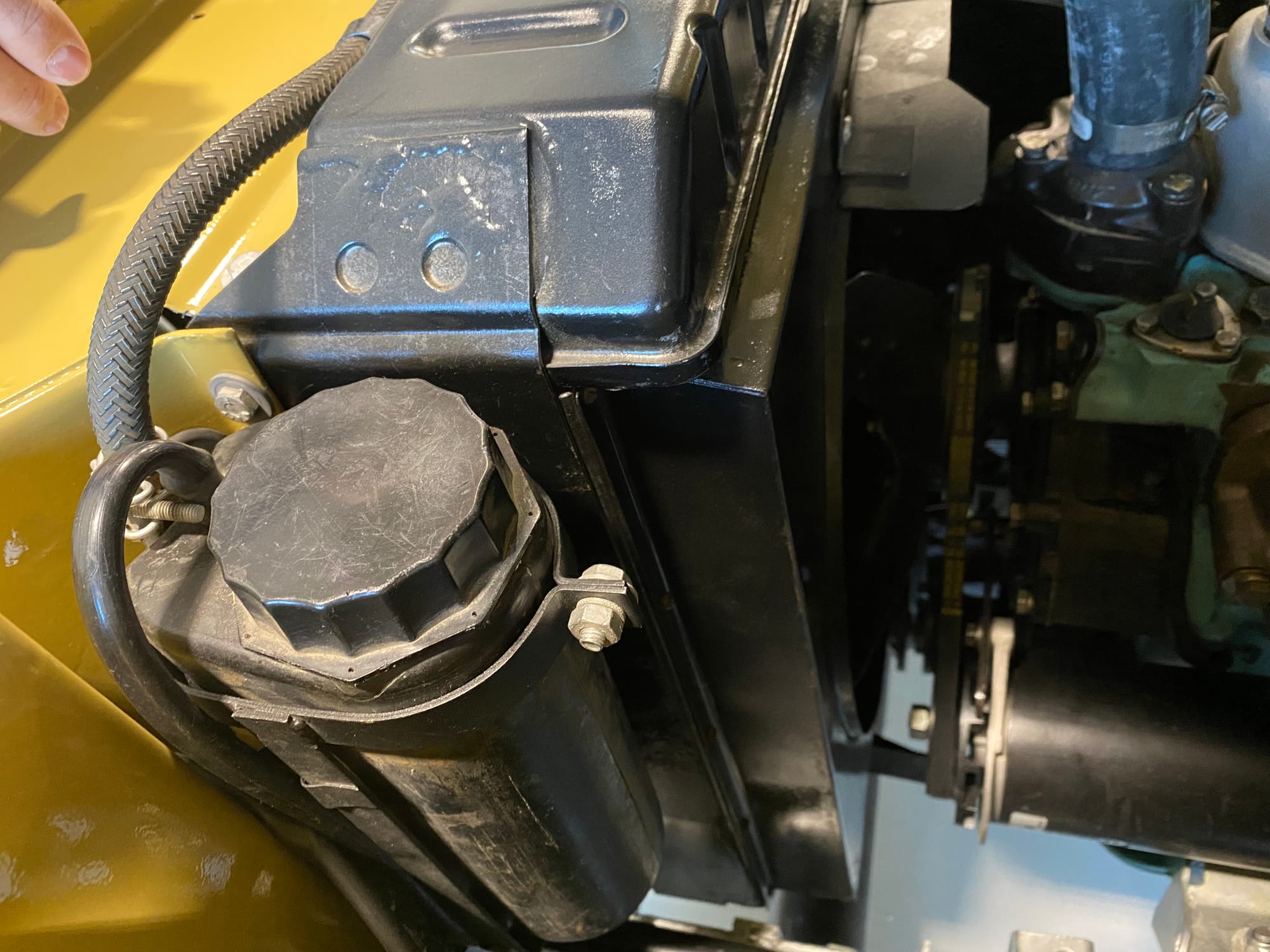

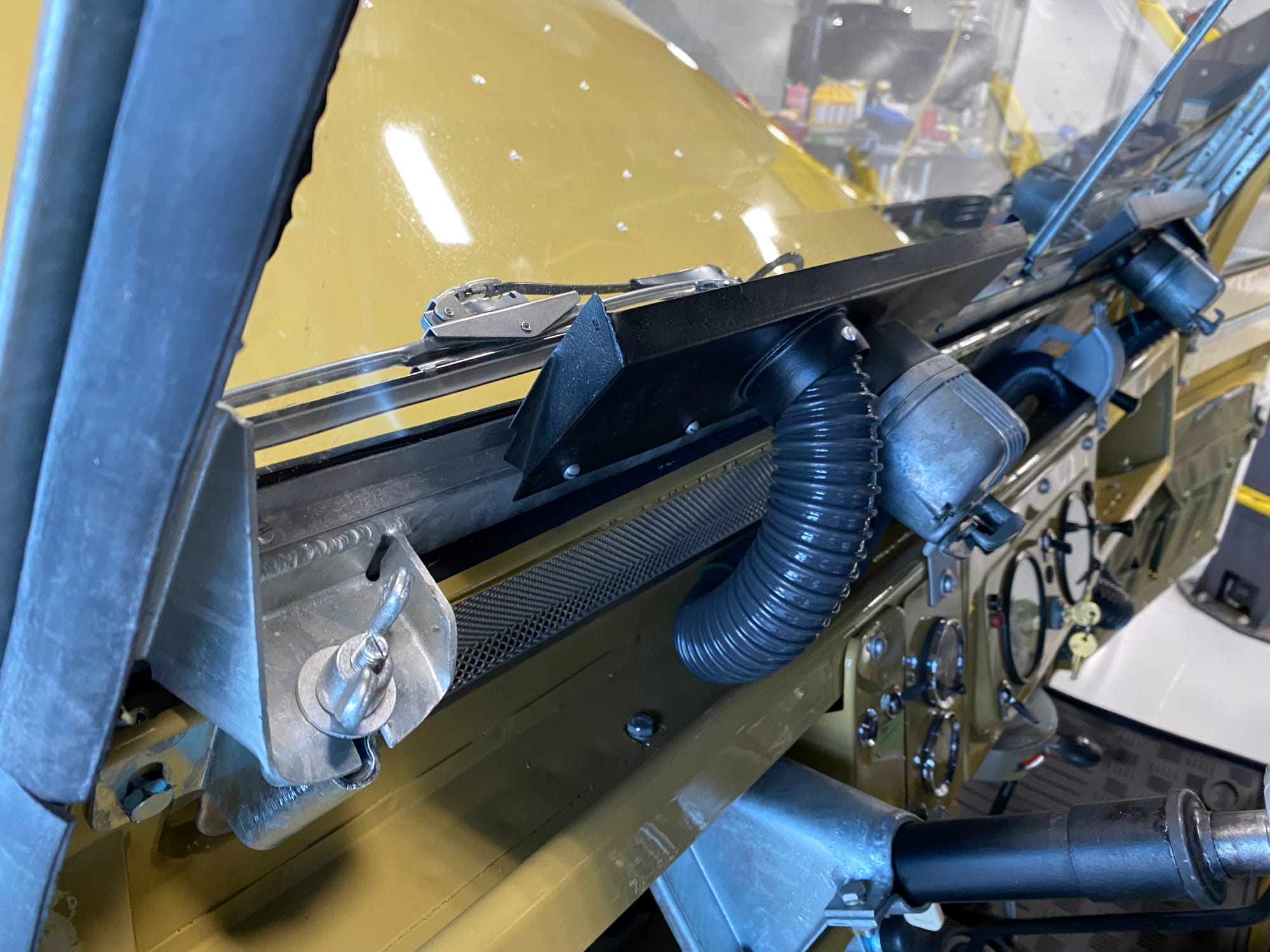

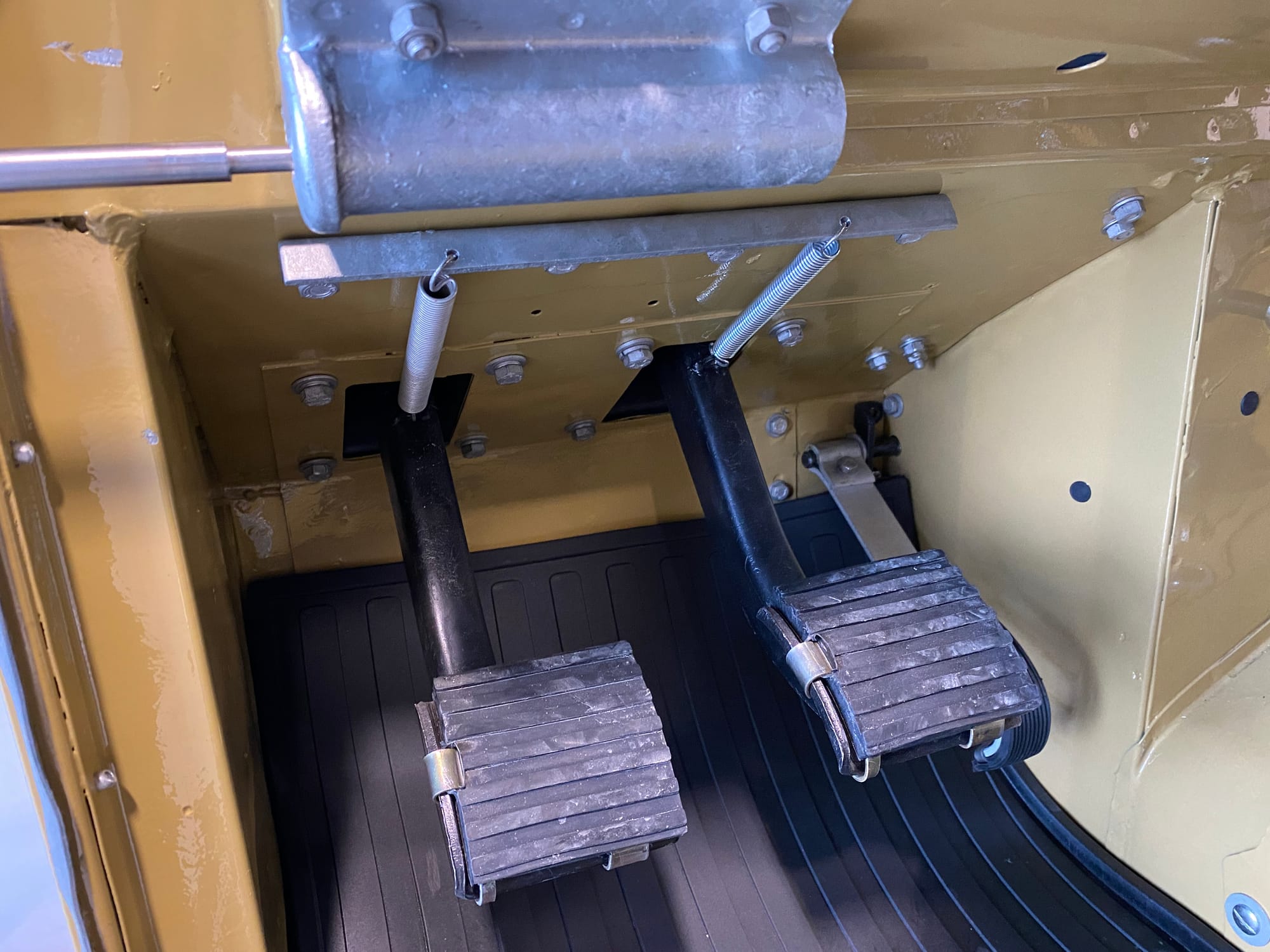

Building up the bulkhead follows with the brake system, throttle linkage and heater.

Rear seats and body hardware was installed in the rear section.

Detail phots show galvanized body cappings and solid-type aluminum rivets, NOS gas cap and side steps. The galvanized cappings for the rear box and the doors are fastened using solid aluminum rivets.

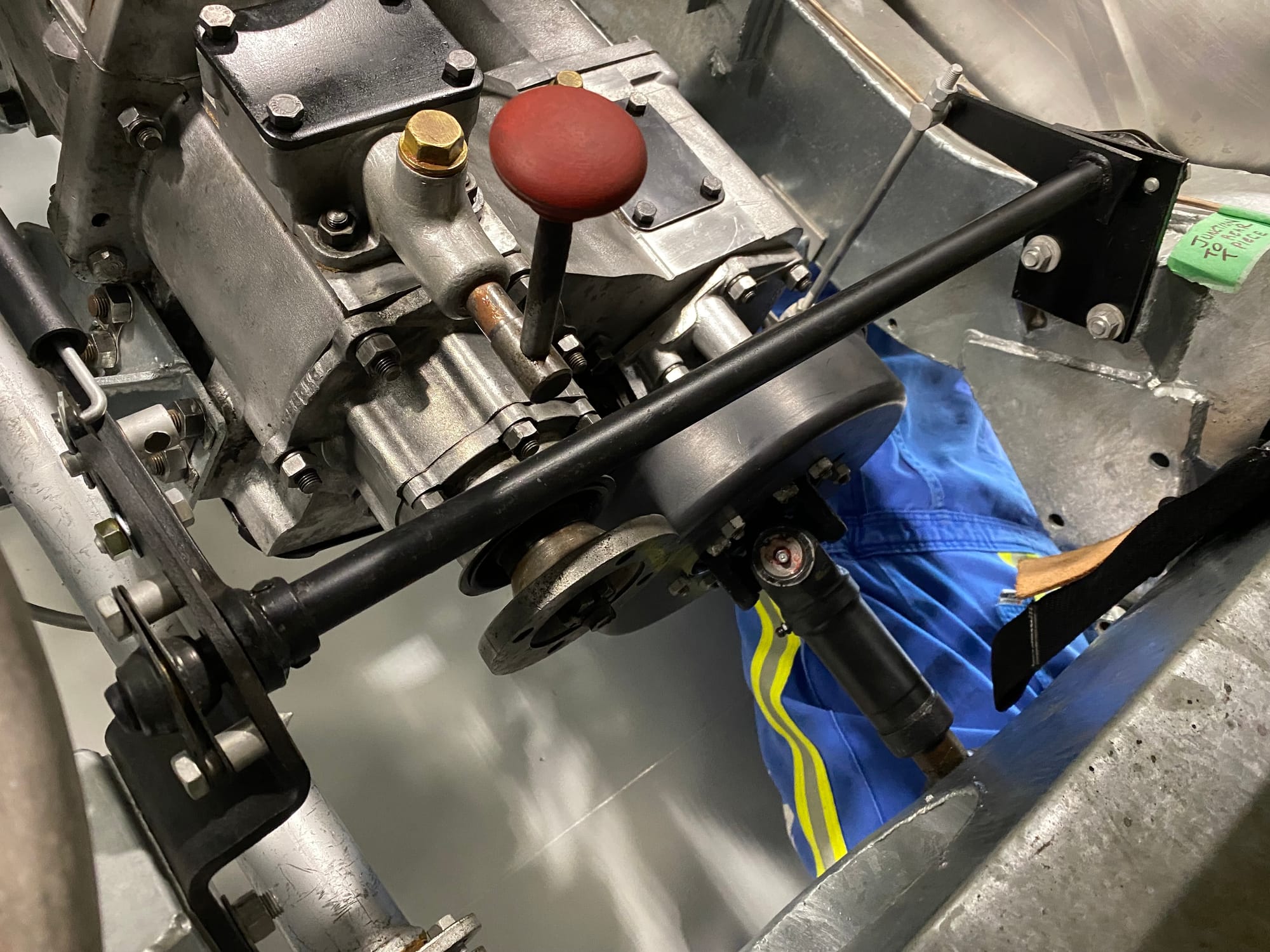

The engine, gearbox and transfer case are now lowered into the vehicle with the seat box removed.

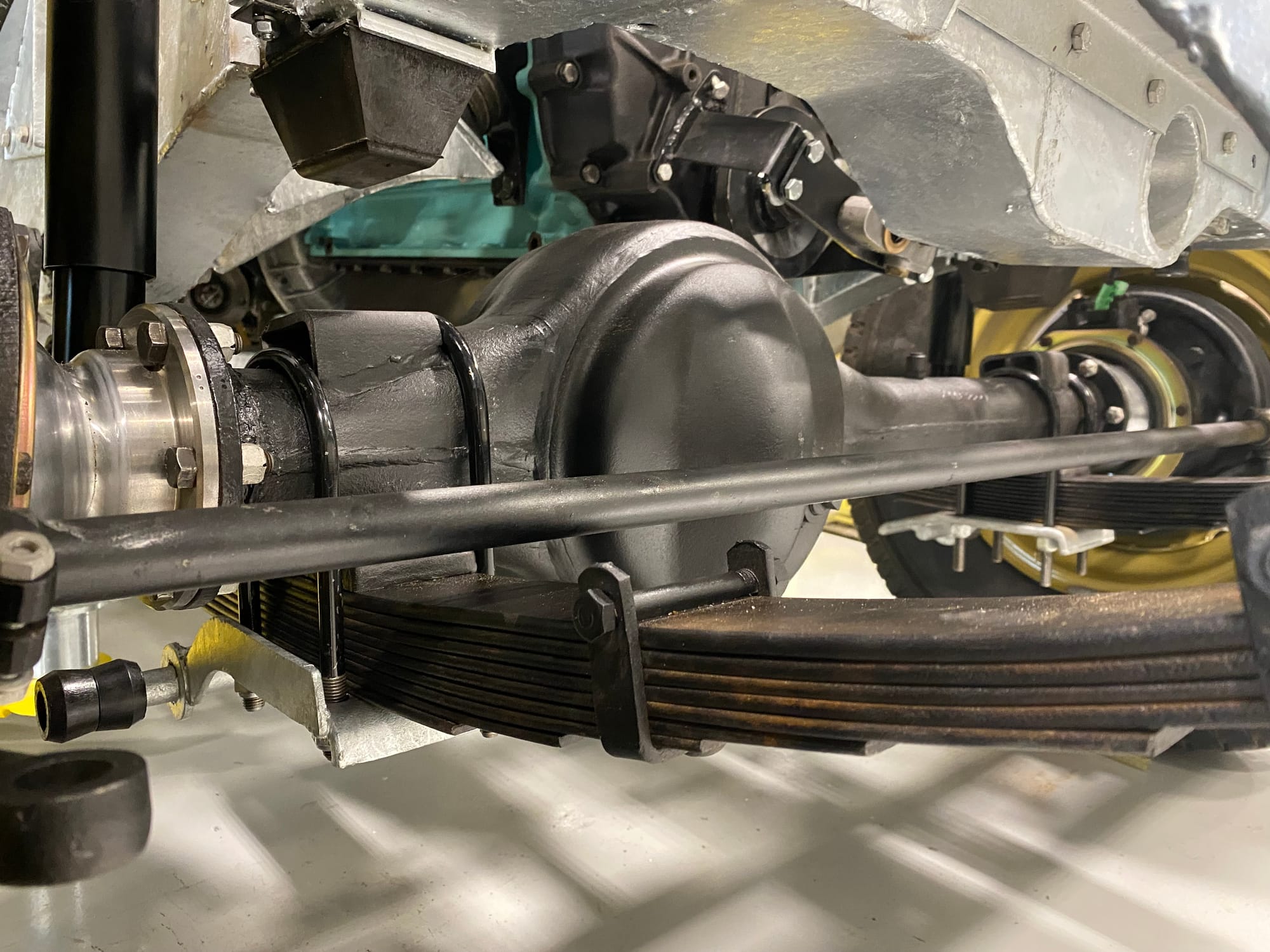

Rear PTO attachement on end of gearbox. This is used to run a rear PTO or bed mounted equipment

The radiator and front grill panel were then installed. With the radiator and grill panel installed, the fenders could be attached.

New Stainless Steel fuel tank from Pangolin 4x4

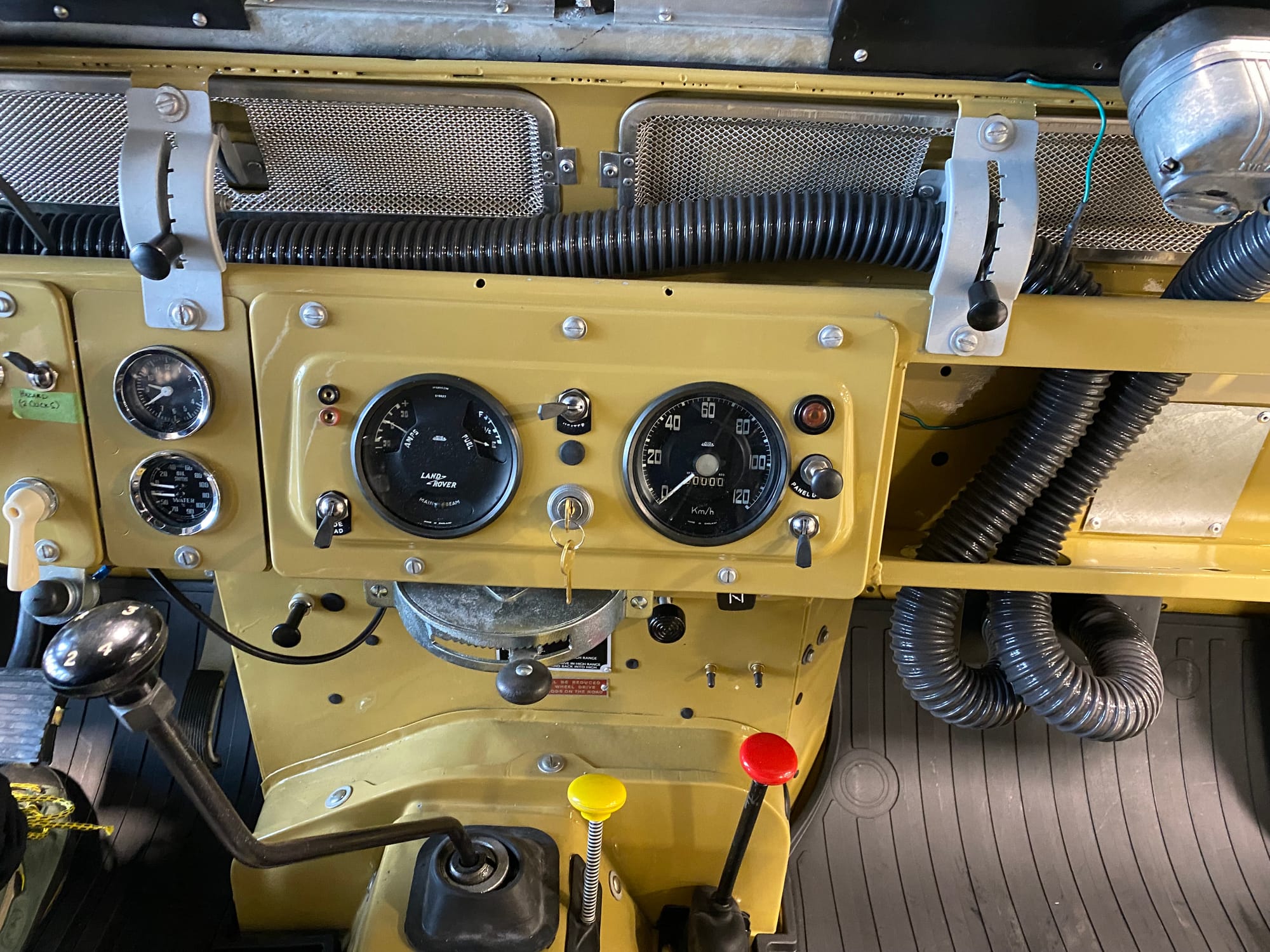

Next, the seat box went back in with seat brackets, seats and ‘vintage racing’ 3” seat belts. Work began on the fitting of the dash, wiring and instrumentation.

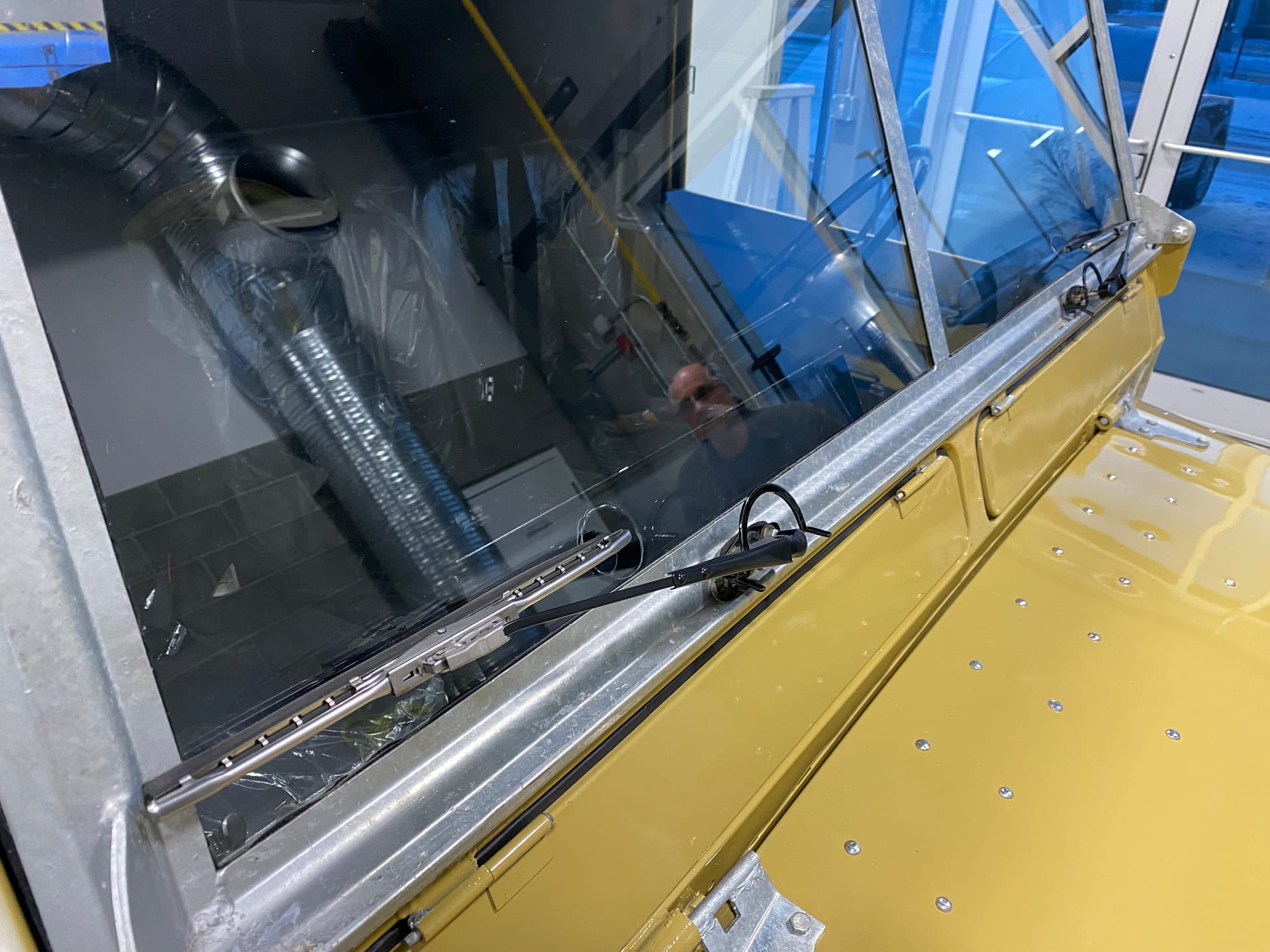

Heater, wiper motors, steering wheel, dust boots for the transmission cover were installed.

New Michelin Latitude truck tires installed on freshly painted NOS rims.

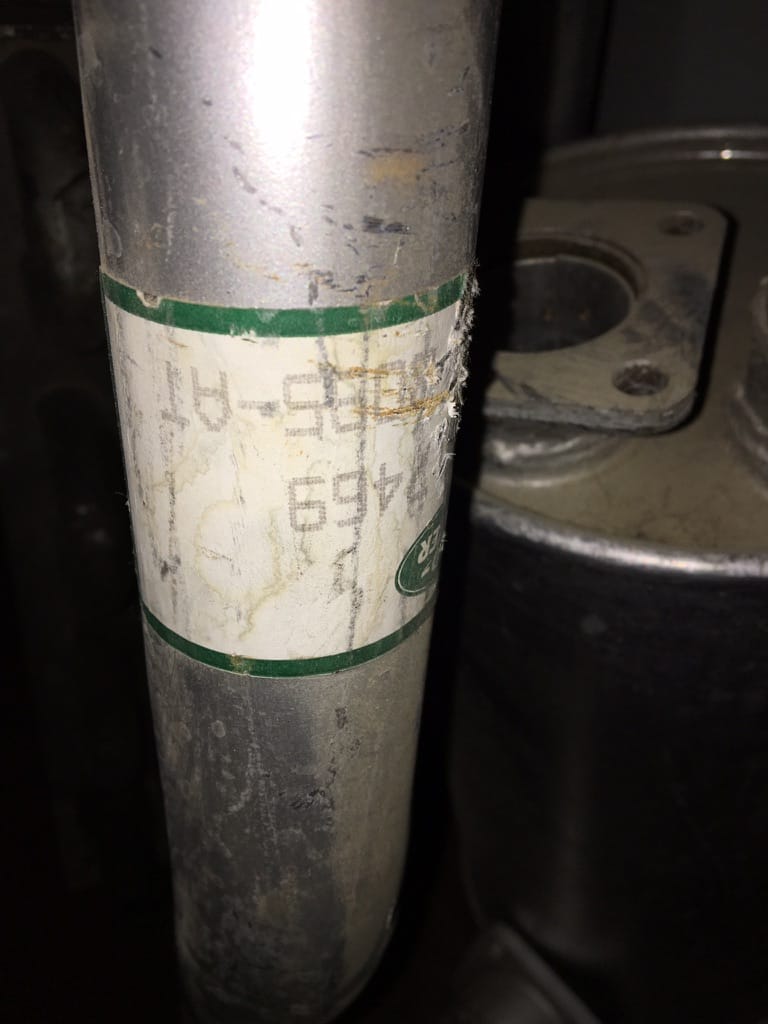

Leaf springs, shocks, check straps, and axle assemblies are bolted together and offered up to the chassis. NOS exhaust shown with live axles and propshafts.

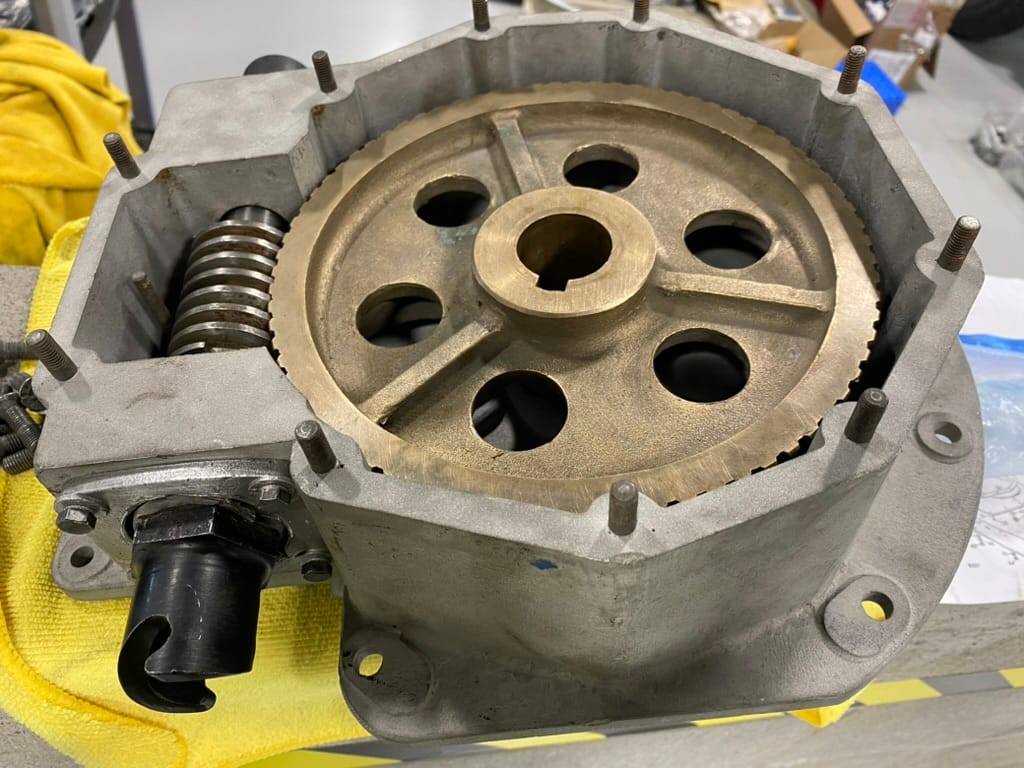

The Capstan winch is a rare and desirable period accessory. The linkage pieces are extremely hard to find, so not many remain operational.

This ‘Aeroparts’ Capstan was fully rebuilt and installed with all the correct linkage pieces.

These Capstan winches require two people to use, and are not easy to operate. Most were replaced with easier to operate electric winches.

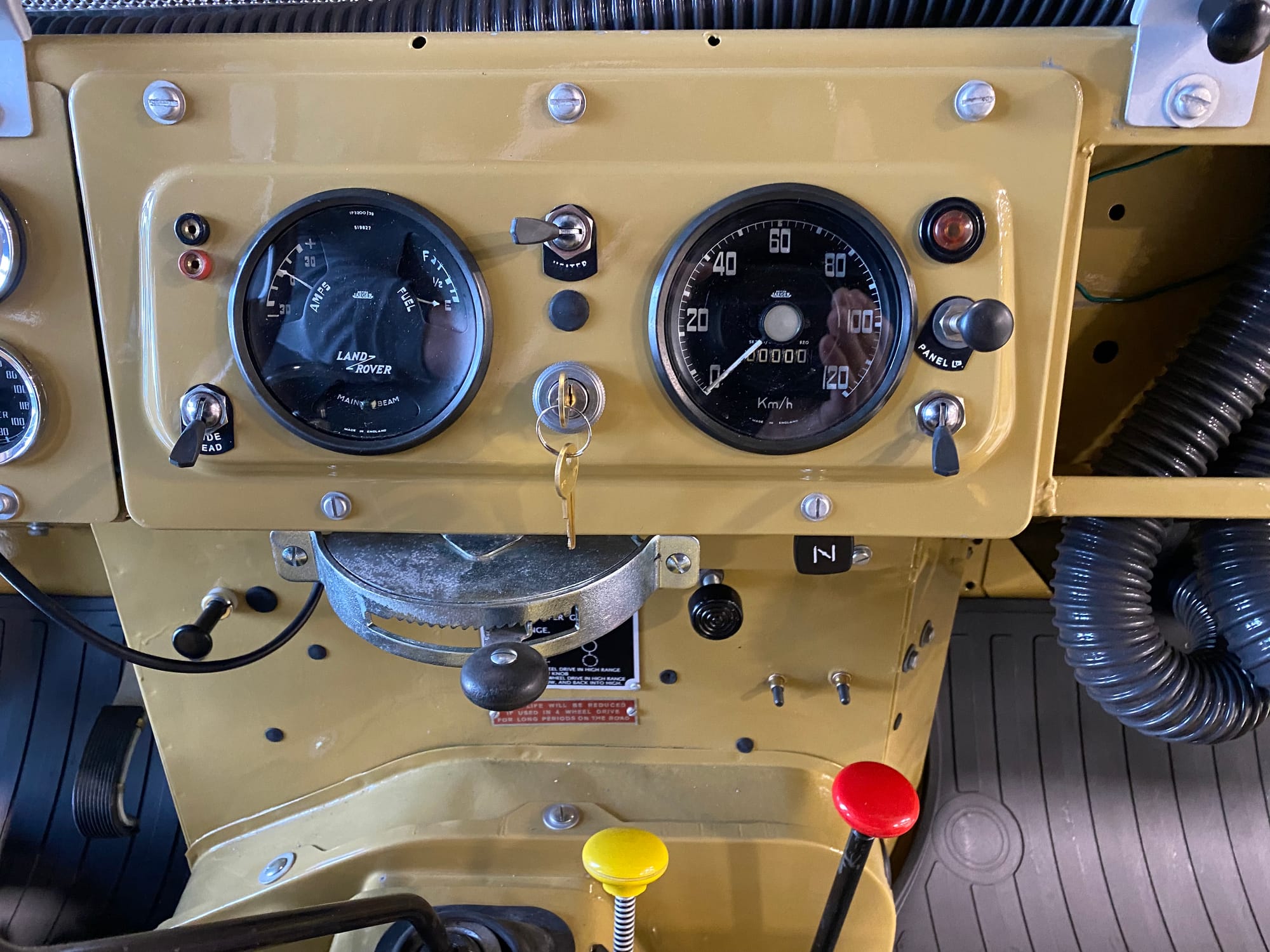

The steering wheel was refurbished, the gauges and switchgear installed in the dash panel and the vehicle’s wiring harness was installed and tested.

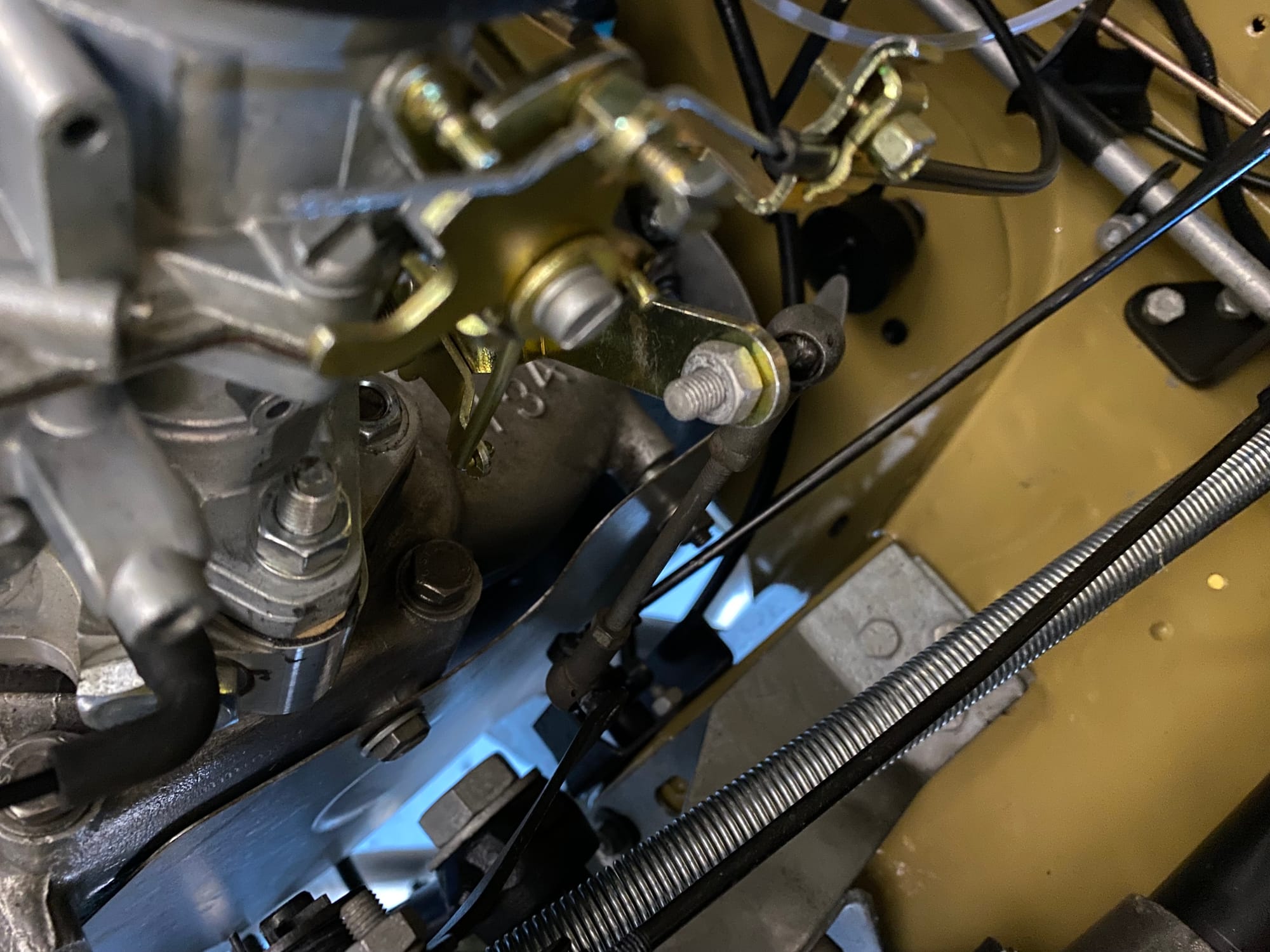

Throttle Linkage

Wiper arms and motors are installed

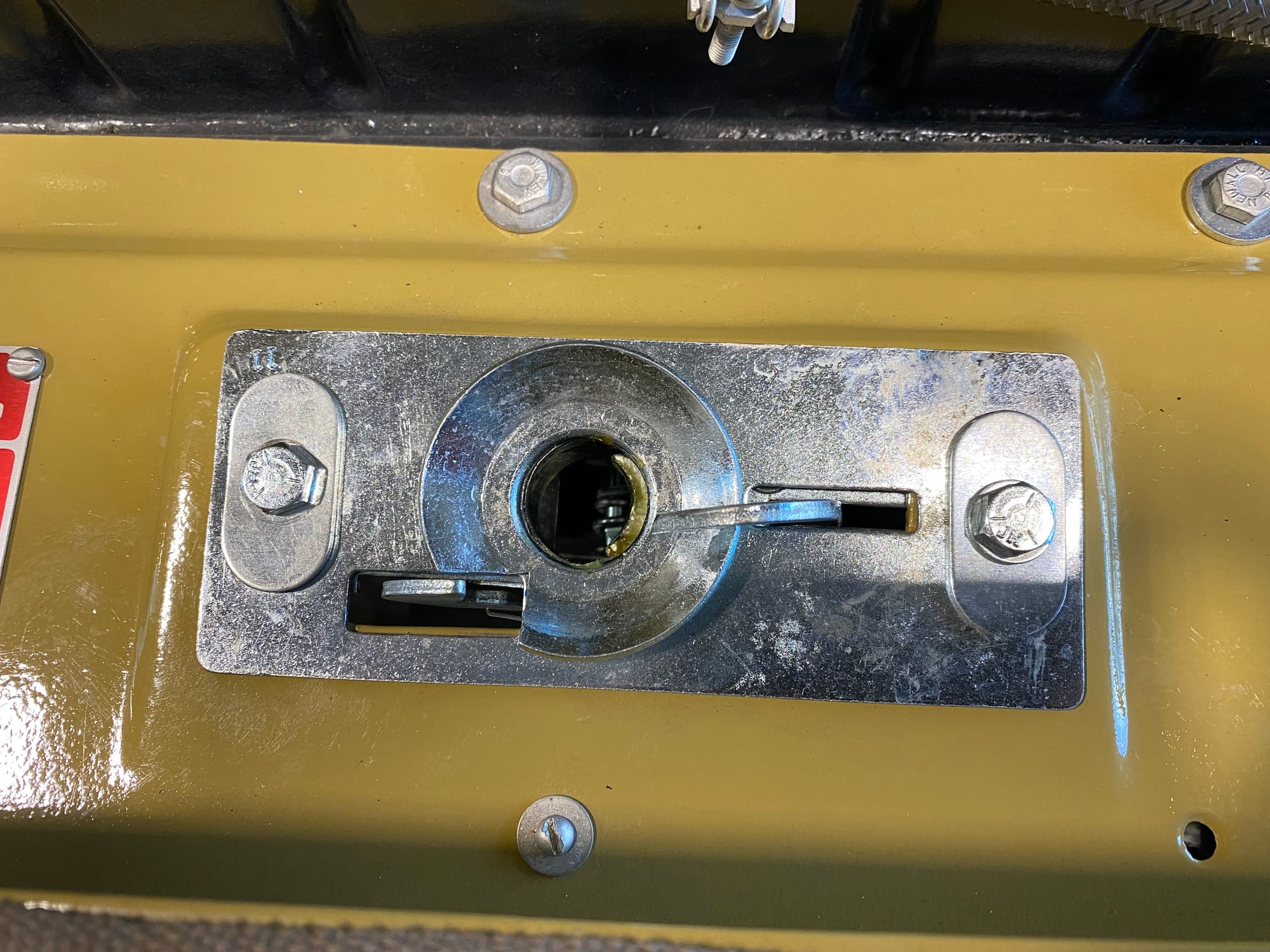

Door lock hardware is zinc electroplated.

Windows were installed with NOS weather seals and window tracks

The canvas top or ‘tilt’ as they say in the UK ,comes from Exmoor Trim, who also supplied the matching door pockets, rear seats, and seat belt anchor bar.

Additional Photos

Comments ()