How Can We Make This More Complicated?

Americans are really good at making simple things that work. Germans are good at making really complicated things that work if you look after them properly. The British, French and Italians make simple and complicated things that may or may not work. Working on a wide variety of machinery, and comparing various engineering solutions to automotive problems, is a constant source of amusement and frustration.

The Hirth roller bearing crankshaft is an example of German complexity at its finest. This German firm patented, in the 1930's, a way to join two stressed shafts together with precision-cut, radially serrated joints. Ferdinand Porsche used Hirth crankshafts in his Auto Union Grand Prix cars of the 1930's. His son Ferry, and engineer Ernst Fuhrmann, used these crankshafts in the Cisitalia Grand Prix car of the Late 1940's and the 4-cam racing engines in the 550 Spyder and the 356 Carrera. Porsche won their class at Le Mans and the Carrera Panamericana with these engines in 1953.

In the 1930's material technology was such that there was no material suitable for plain bearings (where two half bearing shells are installed around a journal on a one-piece crankshaft) that would tolerate the high rpm of a racing engine. By the 1950's, durable alloys and better lubrication made the performance of the plain bearing equal to the roller bearing, at much reduced cost and complexity. Porsche had terrible warranty issues with customer driven 4-Cam 356s as it was imperative to keep the engine revs above 3,000 rpms to avoid pounding the bearings. Not very practical for driving on the street. When you hear the adage, "Dont lug the engine on a sports car", this is where it came from.

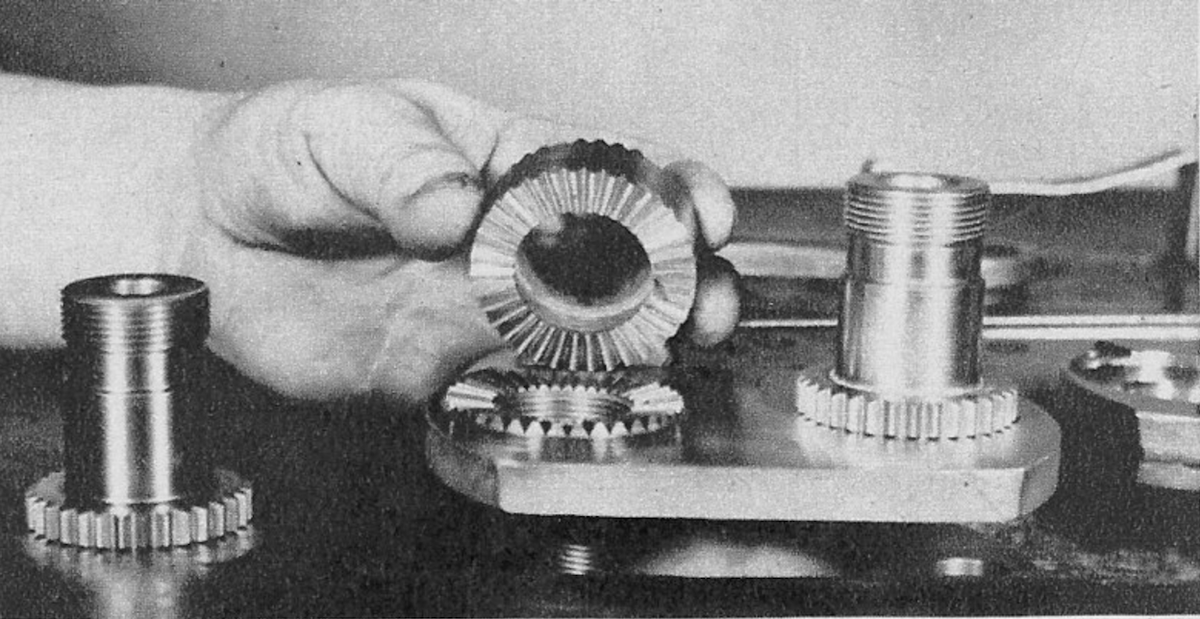

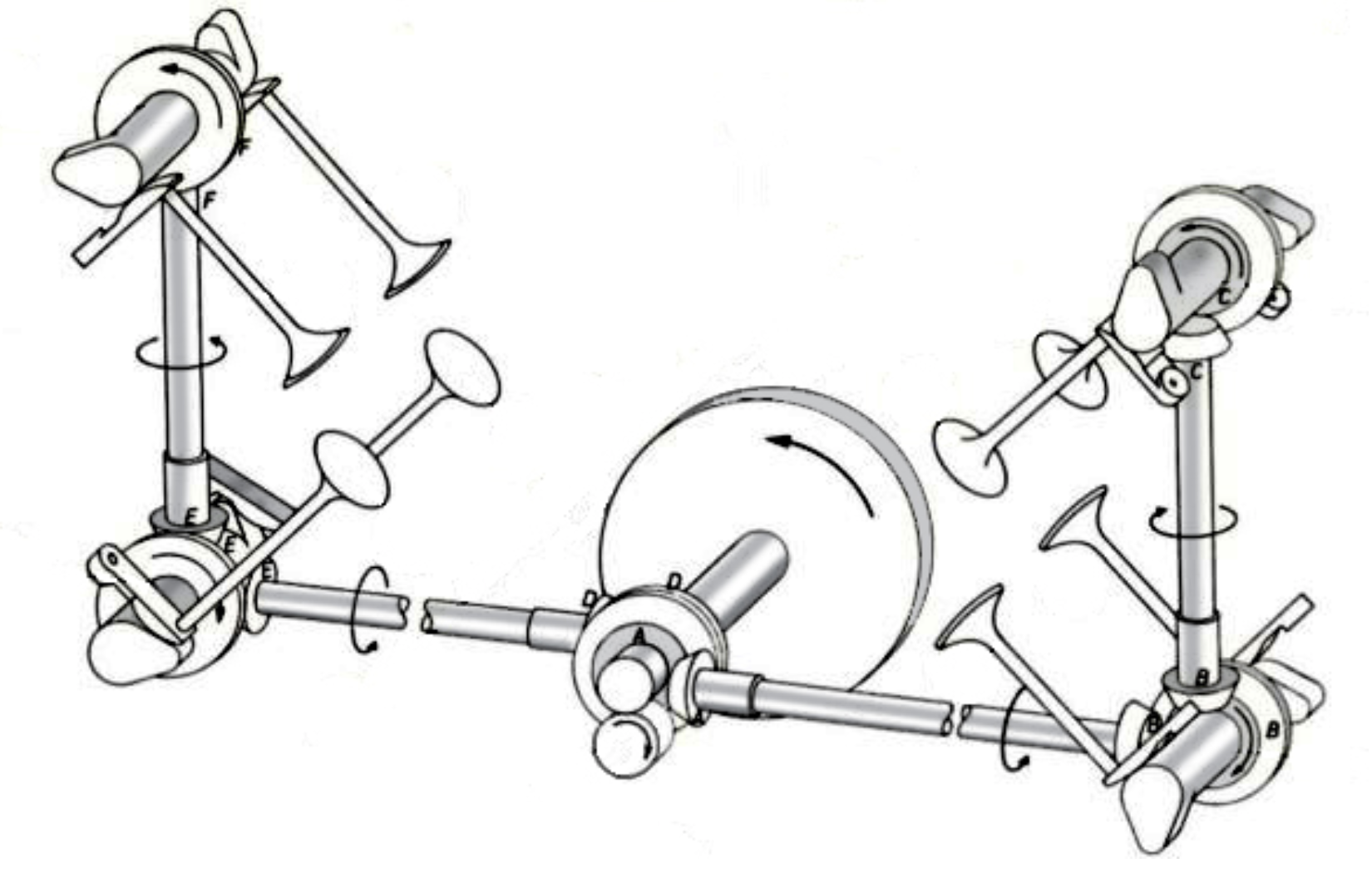

The Fuhrmann engine's complexity didn't end with the crankshaft. Driven off the middle of the shaft for optimum load distribution were vertical shafts and bevel gears where drive was transferred to 4 overhead camshafts. The solution to transferring drive from the crankshaft to the cams is normally done with gears mounted on the front of the engine synchronized with a chain or belt - which is infinitely easier to set up and service. It is apparently a 30 hour job to set the timing on a 4-Cam Carrera engine, and there are only a handful of shops in the world that have the expertise to do so. The cost of a rebuild is well over $USD 100,000 - a lot for 130hp!

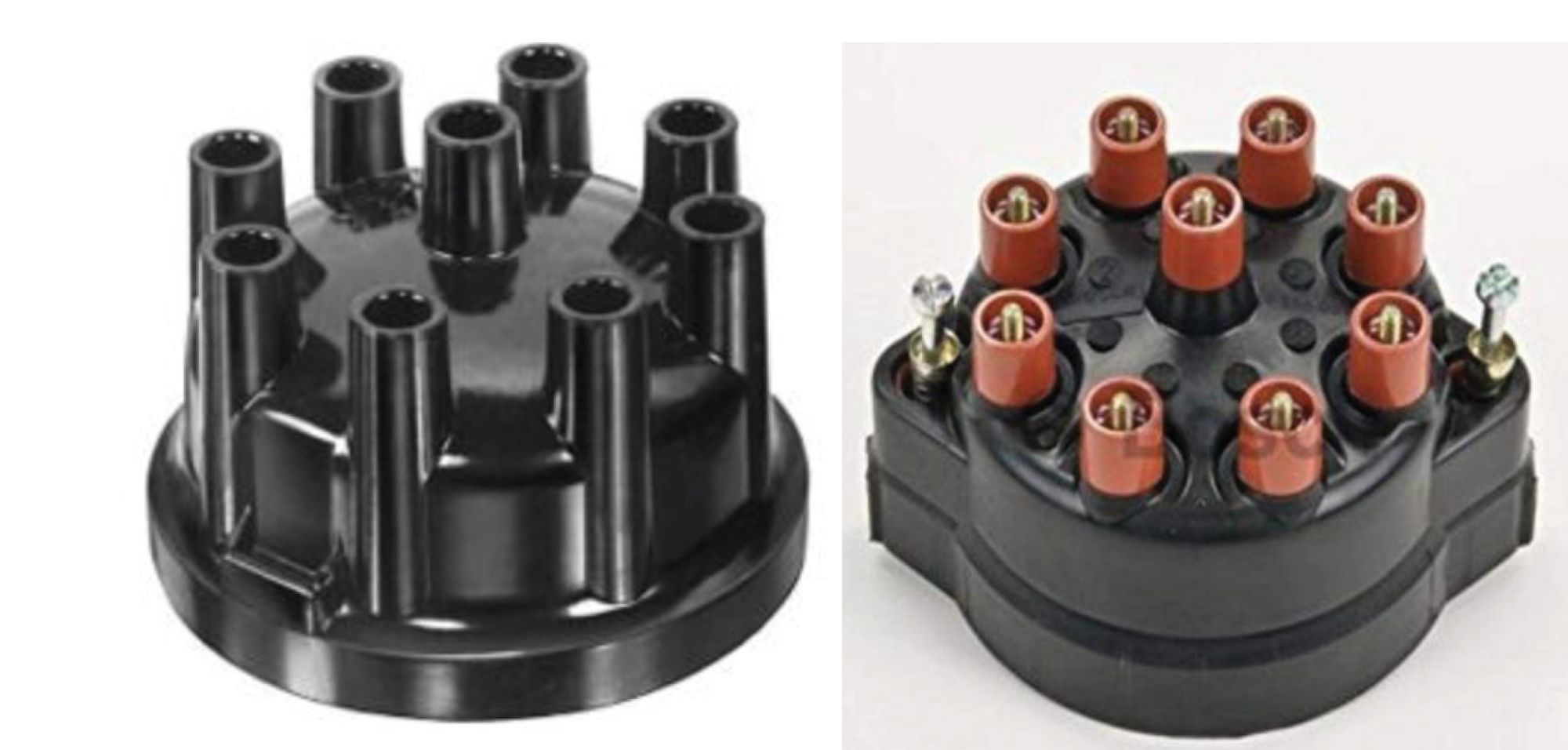

I was reminded of this engine when I unboxed some of the tune-up parts that we received for a 1987 Mercedes-Benz 560SL which is in for service. The car is over 35 years old and the ignition wires, rotor and distributor cap look original. These are 2 or 3 year items in many older cars. Distributor caps for most British cars that I have owned are pretty simple and cheap things - they might cost $30. The Mercedes item was about 10x as much, but was a thing of beauty: copper connections, pressed inserts to accept machine screws and heavy duty construction. This Bosch part was built as well as they could make it without regard for cost. The British item... not so much.

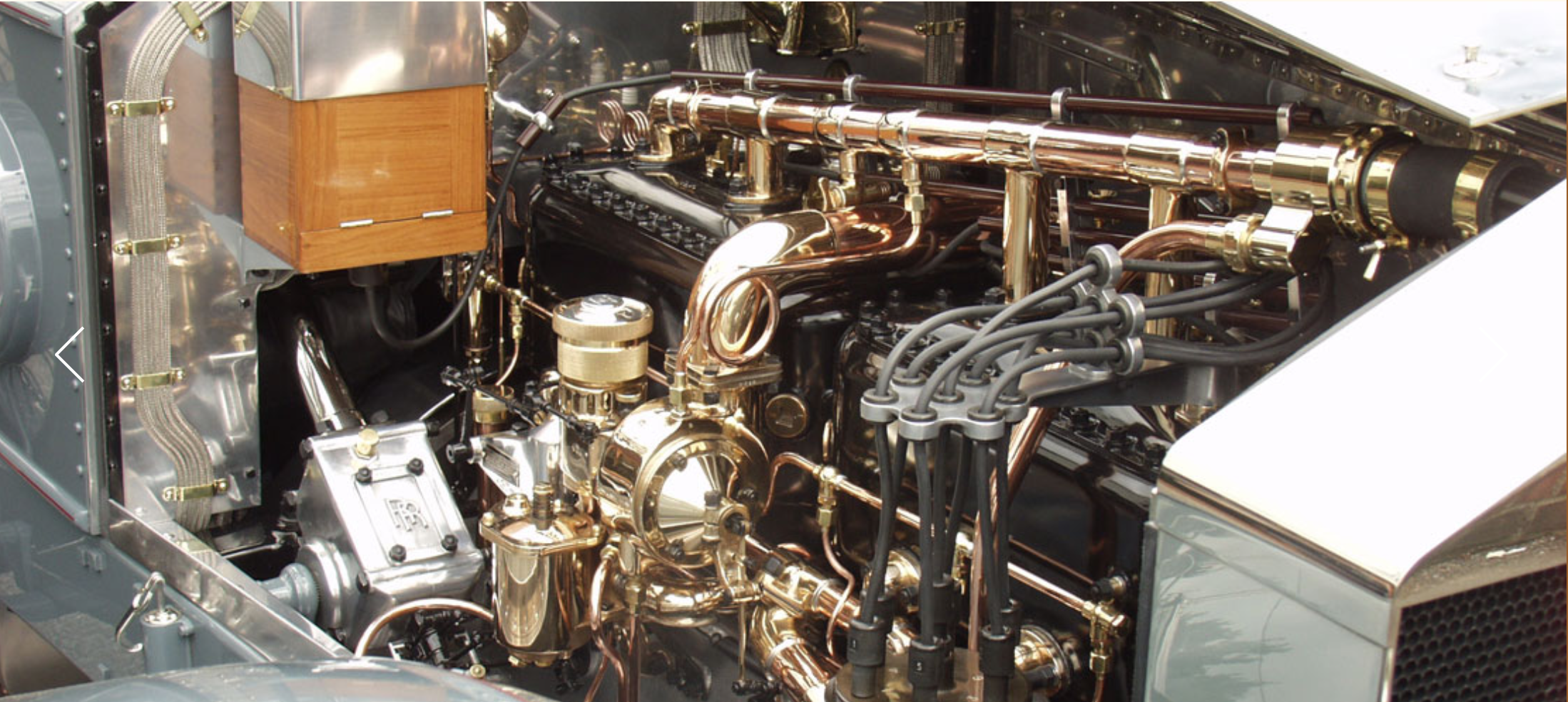

It wasn't always like that. A contemporary of Ferdinand Prosche Sr. was Henry Royce, whose Silver Ghost really was 'The Best Car in The World'. Royce was not credited with many original ideas in the same way Porsche was, but he would start with an existing design and make it better. The two men knew and respected each other, though they were often designing military items for opposing forces. Royce once gave Dr. Porsche the ultimate compliment when he said to one of his engineers, "do it like Porsche does - he always does things correctly". The German Military did not often see it that way, with Porsche's designs too complicated for field work and were often immobilized by unreliability and a lack of spare parts. Albert Speer, Minister of Armaments during WW2, called Porsche 'The Mad Scientist'.

The Ford Model T was made at approximately the same time as the time as the Rolls Royce Silver Ghost (1908-1927 for the Model T, 1906 -1926 for the Silver Ghost), though sold at opposite ends of the price spectrum. Ford viewed the Model T the most perfect car ever built, in large part because of its simplicity, and saw no reason to change it. It was only though intense lobbying by his son Edsel and board of directors that he agreed to add items like an electric starter. By the time the Model A was introduced Ford lost significant market share to General Motors who had embraced annual model changes. Ford did manage to sell over 15 million of them (vs. 7,874 Ghosts) though!

Lawrence Romanosky is a 'Car Guy' running a specialty car service, restoration and brokerage business out of Calgary Canada.

Lromanosky@me.com 403-607-8625

Comments ()